Wire rope is made of steel wires twisted and wound together into a single unit. This tool is commonly used in industries for lifting, pulling, and securing heavy loads.

Therefore, maintaining wire rope performance is crucial. A poorly maintained wire rope can suffer from issues such as kinks or breakage, which can lead to serious accidents.

Proper Ways to Maintain Wire Rope

Look for signs of damage such as:

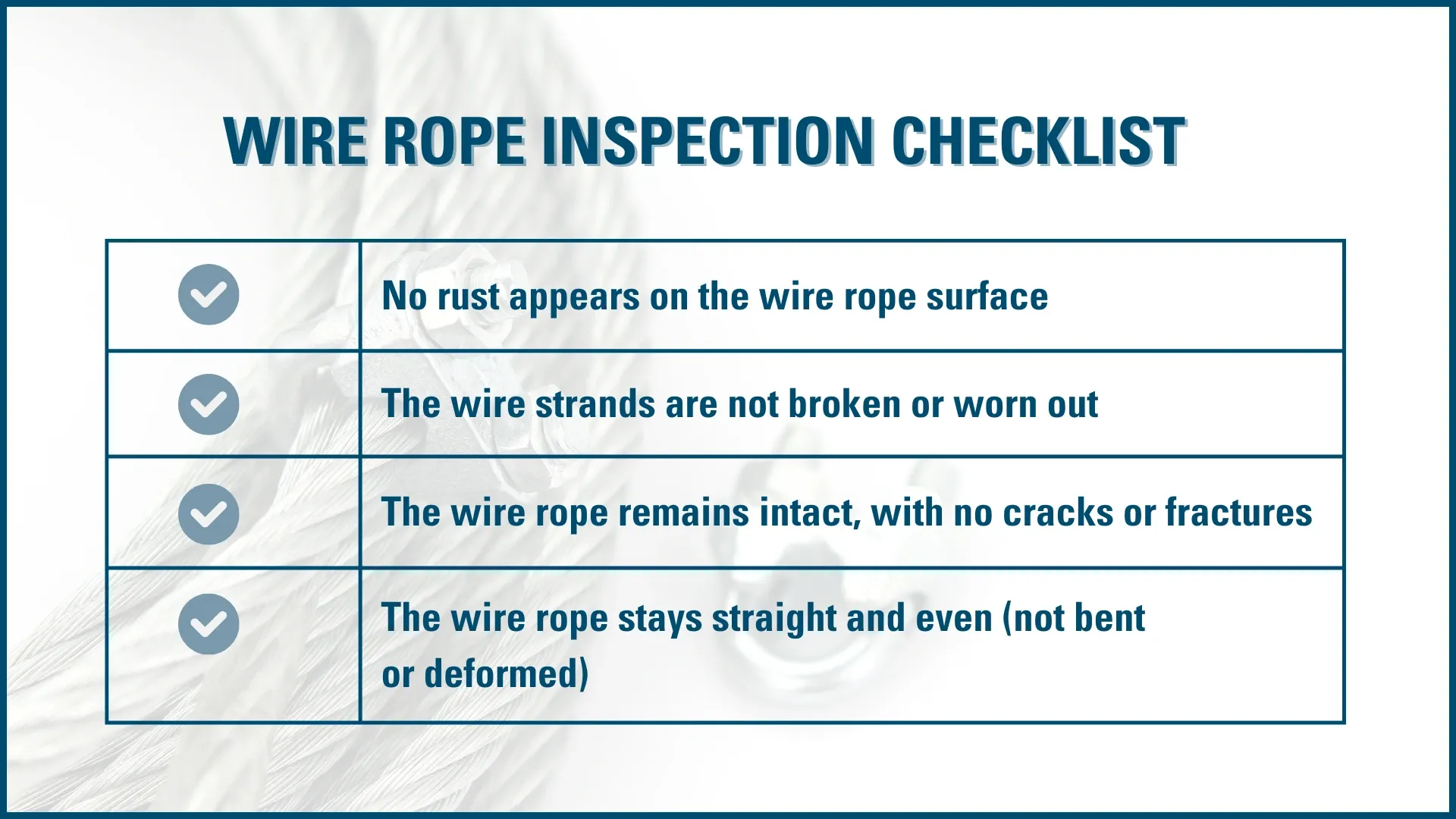

✅ Rust formation on the wire rope’s surface.

✅ Broken or worn-out strands of wire.

✅ Fractures or cracks in any part of the wire rope.

✅ Bending or uneven shape of the wire rope.

Regular inspections not only ensure safety but also improve work efficiency.

2. Clean the Wire Rope Regularly

Dust and dirt can accumulate on the wire rope’s surface, affecting its strength and flexibility. Clean the wire rope regularly using a specialized brush.

Use a suitable cleaning solution to avoid damaging the material. Never allow dirt to remain for too long, as it can lead to rust. Cleanliness is the key to proper maintenance.

3. Lubricate the Wire Rope

Lubrication helps reduce friction in the wire rope. Use a lubricant specifically designed for wire ropes for the best results. Proper lubrication maintains flexibility and protects against corrosion. Ensure that the lubricant is evenly distributed across the entire wire rope, including the smallest gaps.

4. Schedule Periodic Inspections

Regular detailed inspections are essential to detect damage early. Check for:

🔍 Broken wires

🔍 Deformation

🔍 Signs of excessive wear

If any damage is found, replace the affected section immediately. Do not delay, as minor issues can escalate and disrupt operations.

5. Avoid Overloading

Every wire rope has a specific load capacity. Never exceed the recommended weight limit set by the manufacturer. Overloading accelerates wear and tear, reducing the rope’s lifespan. Always ensure usage aligns with technical specifications.

6. Store Wire Rope Properly

Storage conditions also affect the lifespan of wire rope. Store in a dry place, away from harmful chemicals. Avoid humid areas to prevent corrosion. Proper storage maintains the wire rope’s quality for long-term use.

Inspection Checklist for Wire Rope

An Essential Investment for Operational Safety

Maintaining wire rope is an important investment to ensure smooth and safe operations. With the right and consistent approach, the risk of damage can be minimized.

SpanSet is a leading company providing a wide range of lifting equipment, including high-quality wire ropes. SpanSet products are engineered for optimal performance and superior safety.