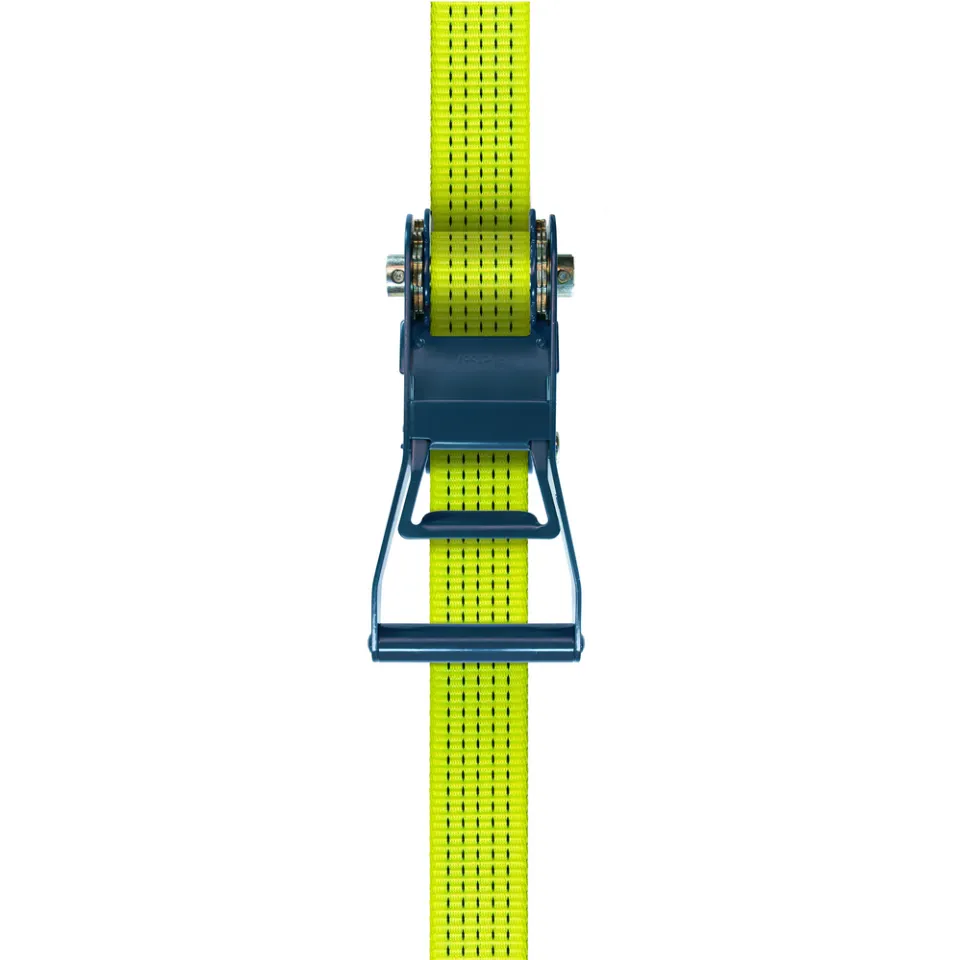

Zurrgurt Typ ABS50 mit ABS-Ratsche und Triangelhaken

CHF 117.70

exkl. MWST

Zurrgurt Typ ABS50 mit ABS-Ratsche und Triangelhaken

Zweiteiliger 50 mm-Zurrgurt, mit ABS-Ratsche, LC 2'500 / 5'000 daN

CHF 117.70

exkl. MWST

Voraussichtliche Lieferzeit ca 3 Tage

- Epoxidharz beschichtete Ratsche

- Doppelschieber für leichteres Spannen

- ABS-System für stufenweises lösen

- Vorspannkraftanzeige TFI

- Selbstverriegelnder Ratschenhebel

- Reissfestes Qualitäts-Label mit Schutzschlauch

Modell auswählen

CHF 117.70

exkl. MWST

Voraussichtliche Lieferzeit ca 3 Tage

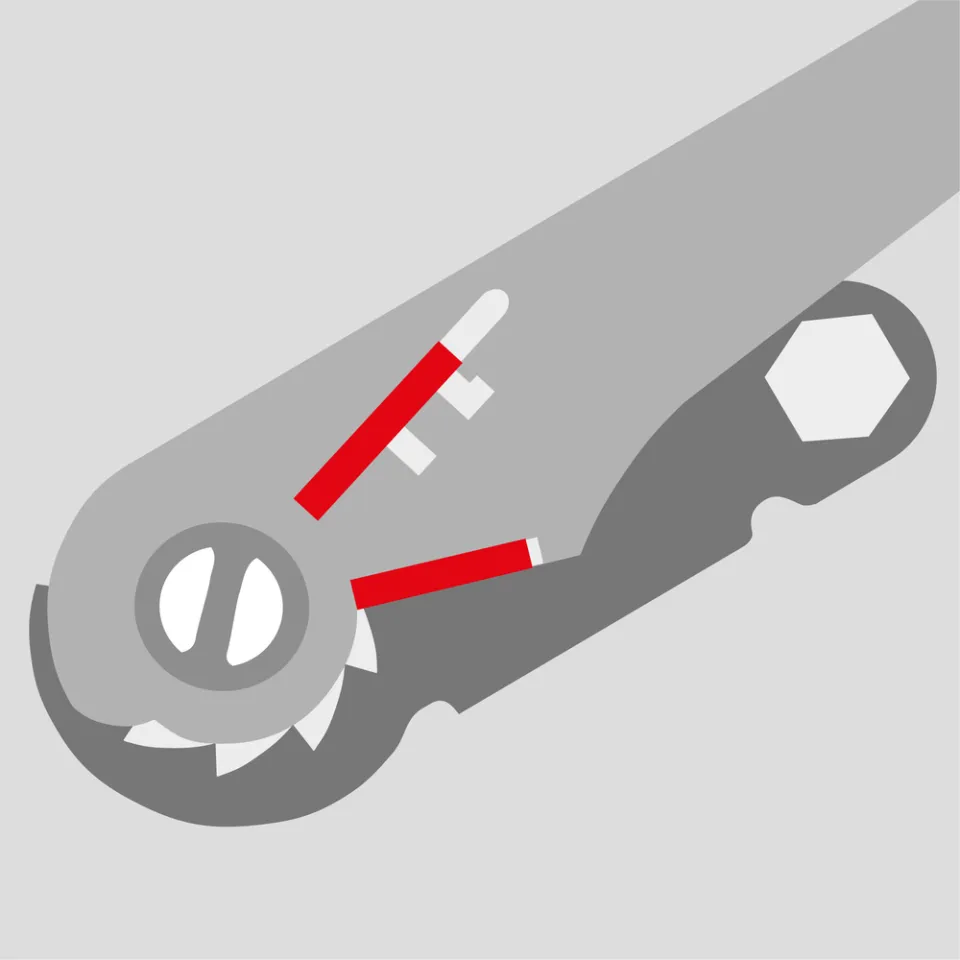

Selbstsichernder Ratschenhebel

verhindert das unbeabsichtigte Öffnen der Ratsche

Für maximale Sicherheit beim Zurren haben wir den selbstsichernden Ratschenhebel entwickelt. Beim Zurren zieht man den integrierten Funktionsschieber. Schließt man die Ratsche, rastet er automatisch in der Sicherungsposition ein. Ein unbeabsichtigtes Öffnen der Ratsche im Fahrbetrieb ist dadurch wirksam ausgeschlossen – selbst bei stärksten Vibrationen und Rüttelbewegungen.

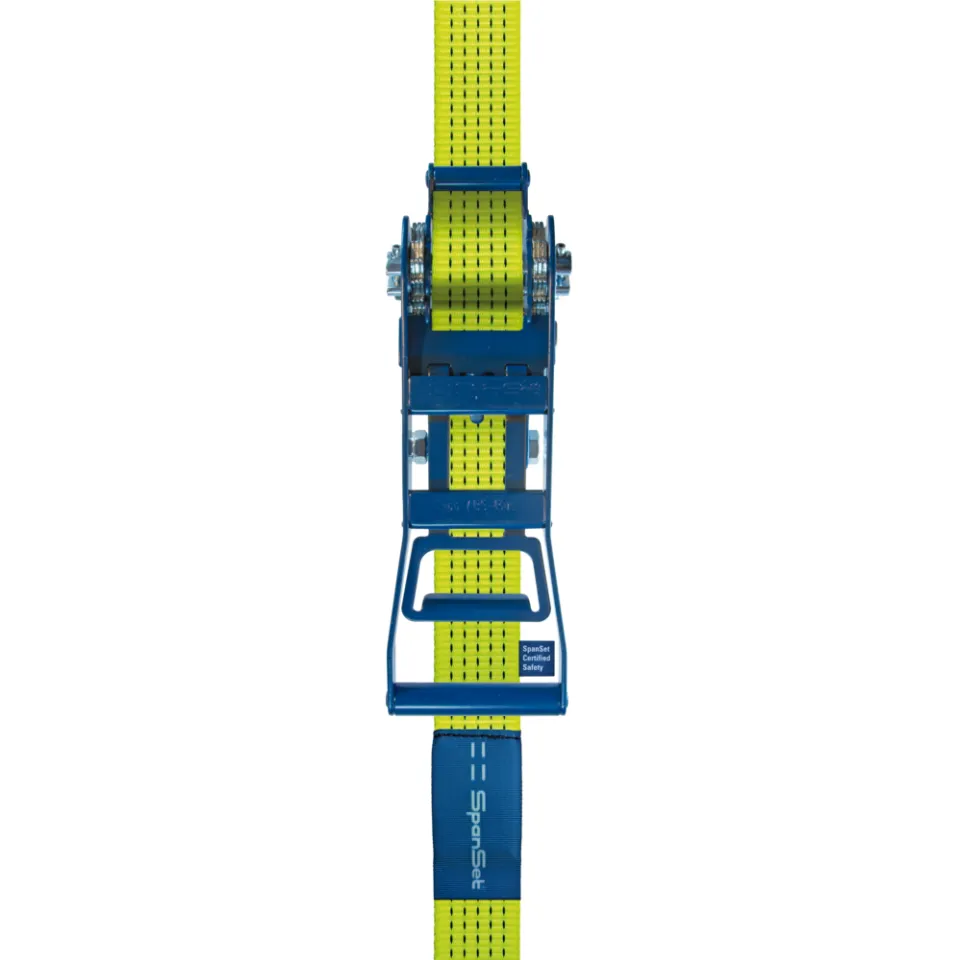

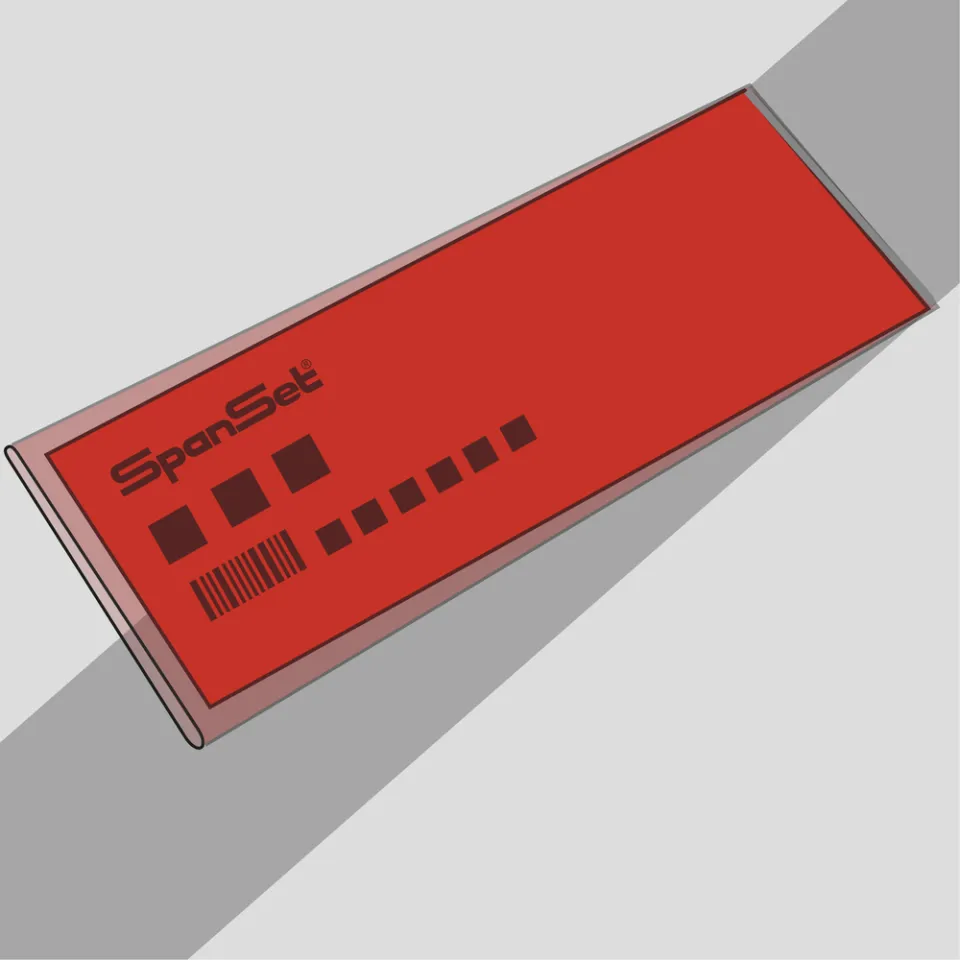

Schutzschlauchlabel

optimal geschützt, mit Einlage verstärkt

Neben der ausreißfesten Verarbeitung durch Gewebeeinlage schützt ein robuster Folienschlauch die Beschriftung bestens vor Abrieb und Verschmutzung. Die serienmäßige Gurtbandüberlappung ist zusätzlich standzeiterhöhend.

Epoxidharzbeschichtung

Beschichtung auf chromatierter und verzinkter Stahlblech-Ratsche

Wir legen größten Wert auf Qualität in jedem Einzelteil. Die Ratschen werden erst verzinkt, dann chromatiert und mit einer schlagfesten Epoxidharzbeschichtung überzogen, die die Ratschen zusätzlich z.B. vor Rostbildung schützt.

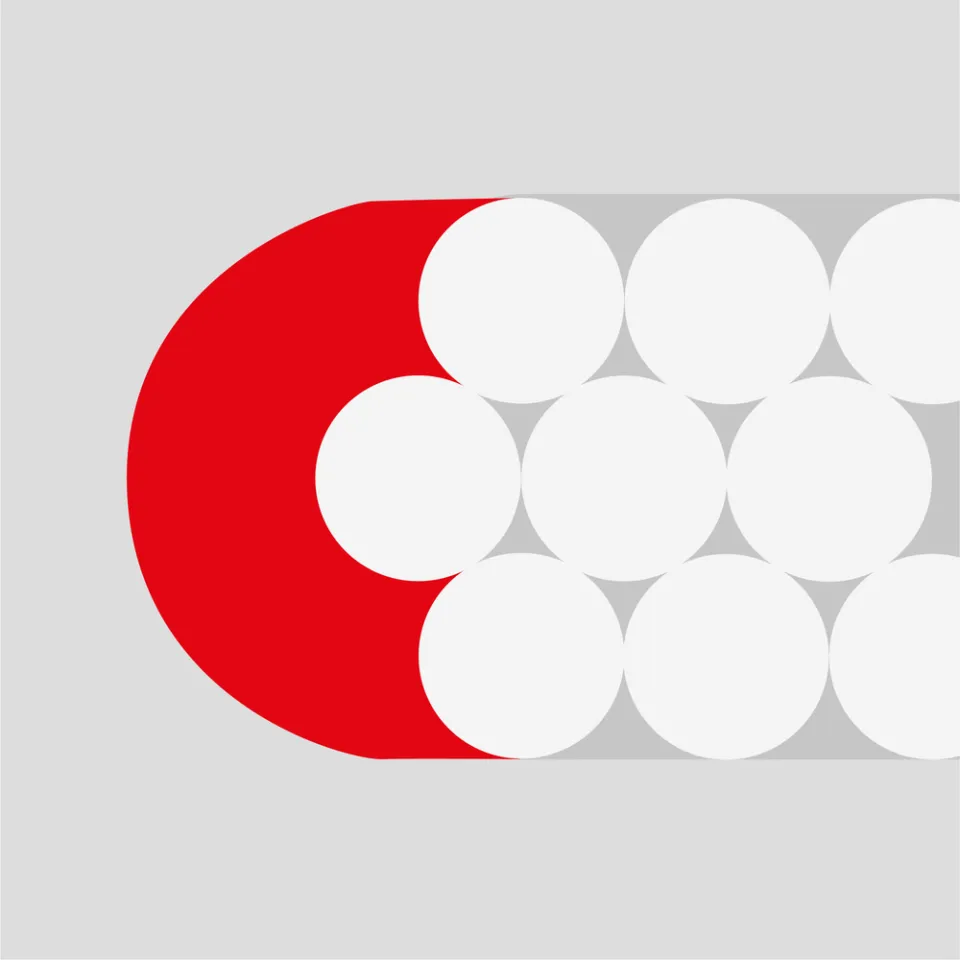

Tension Force Indicator

Anzeige zum Nachweis der tatsächlich erreichten Vorspannkraft

Mit dem TFI können Sie die beim Niederzurren in das Zurrsystem eingebrachten Vorspannkräfte nachweisen und in die Berechnung der Ladungssicherung übernehmen. Drei Varianten des TFI mit 500 (grün), 750 (rot) und 1.000 daN (gelb) stehen zur Verfügung. Besonders effektiv ist die Verwendung von einem TFI an Los- und Festende, womit 1.000, 1.500 und 2.000 daN Vorspannkraft nachgewiesen werden können. Infolgedessen werden weniger Zurrmittel für die Ladungssicherung benötigt, was das Be- und Entladen beschleunight und große wirtschaftliche Vorteile bedingt.

Zweifachschieber

mehr Spannkraft, weniger Muskelkraft

Der Zweifachschieber sichert beim Spannen des Zurrgurtes auch in der Zwischenstufe. Zwei Schieber greifen in einen bestehenden Zahnkranz „kleinschrittiger“ ein. Dadurch erreichen Sie mehr Spannkraft und schonen so Ihre Muskelkraft.

„Anti-Belt-Slip“-Verfahren

ermöglicht, die Vorspannung in kleinen Schritten freizugeben

Die Ratsche wird geöffnet, die Spannung löst sich ruckartig und die Ladung gerät außer Kontrolle: Wer das einmal erlebt hat, weiß, wie wichtig ABS ist. Das ABS-System ist für „kippgefährdete“ Ladungen entwickelt worden und erlaubt, die Vorspannkraft in kleinen Schritten freizugeben. Dadurch haben Sie die Möglichkeit, kippgefährdete Ladung, die sich in den Gurt neigt, aufzurichten. Das hilft, Schäden und Unfälle zu vermeiden. Das Zurrsystem kann auch direkt vollständig geöffnet werden, so verliert man beim Transport von standfester Ladung keine Zeit.

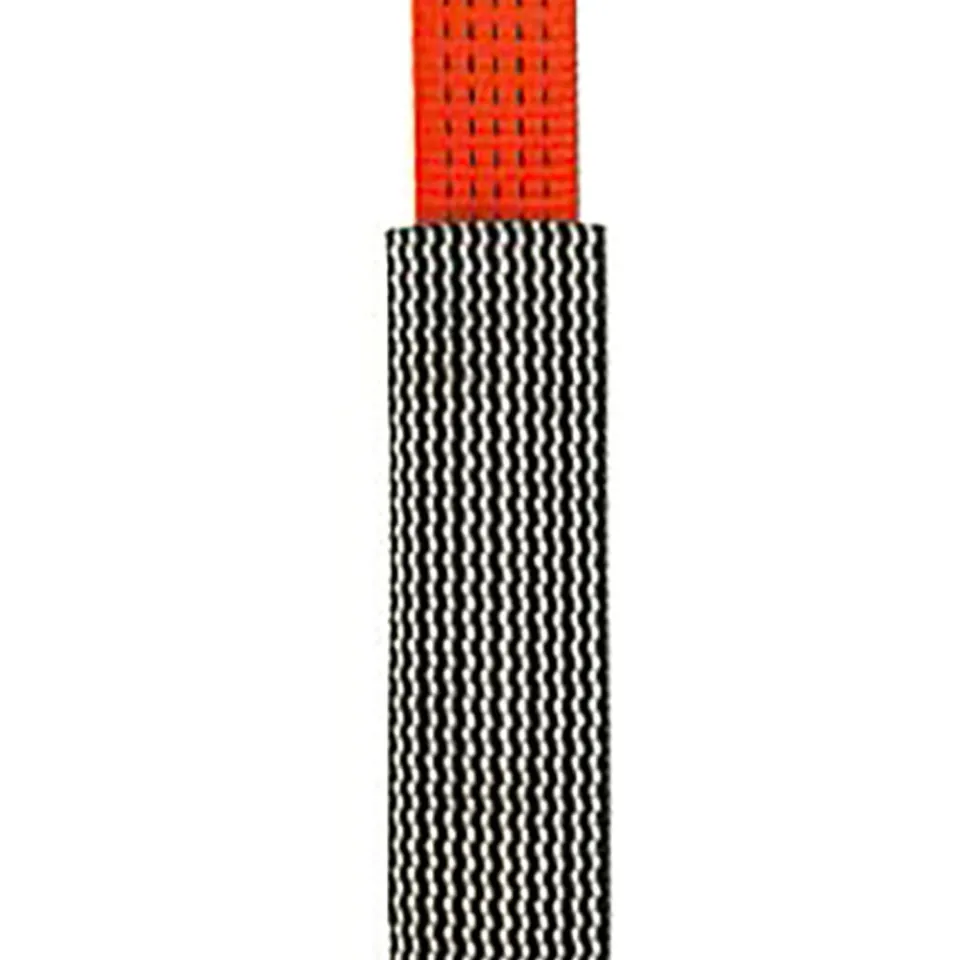

Verstärkte Webkante

macht Gurte unempfindlicher gegen Verschleiß und Abrieb

Gurtbänder mit der verstärkten Webkante sind unempfindlicher gegen Verschleiß und Abrieb. Ihr Vorteil: längere Standzeiten und geringere Kosten!

Präzisions-Gurtband

geringe Dehnbarkeit des Gurtbandes

Spannfix-Ratschen entsprechen mit einer Gurtbanddehnung von weniger als 7% der Norm. Unsere Qualitätssysteme weisen sogar nur 4% Gurtbanddehnung auf. Weniger Dehnung ist rationeller, da weniger häufig nachgespannt werden muss.

Zweifachschieber

Der Zweifachschieber sichert beim Spannen des Zurrgurtes auch in der Zwischenstufe. Die beiden Schieber greifen abwechslungsweise und in kleineren Schritten als vergleichsweise bei Ratschen mit nur einem Schieber, in den Zahnkranz ein. Dadurch erreichen Sie mehr Spannkraft und schonen dabei Ihre Muskelkraft.

Verstärkte Webkanten

Spanset® Zurrgurtenbänder mit der verstärkten Webkante sind gegenüber konventionellen Bändern wesentlich unempfindlicher gegen Verschleiss und Abrieb. Die Bänder können daher länger eingesetzt werden. Damit sparen Sie Zeit und Kosten.

Die ABS-Ratschen ermöglichen eine kontrollierte Freigabe der Vorspannkraft (STF) durch das Anti-Belt-Slip-Verfahren (ABS). Bei Zurrgurten ohne ABS-System wird die komplette Vorspannung auf einmal gelöst. Bei einer instabilen Ladung wie z. B. Rohren, kann dies zu schweren Unfällen führen. Nicht so bei der ABS-Ratsche, kommt die Ladung in Bewegung, können noch Gegenmassnahmen getroffen werden ohne das Mensch oder Material gefährdet werden. Selbstverständlich kann die Vorspannung bei stabiler Ladung auch auf einmal gelöst werden.

Gelb steht für SpanSet®-Premiumqulität

Bei Zurrgurten steht meistens das Spannelement im Vordergrund. Dabei wird ein ebenso wichtiger Bestandteil eines Zurrgurts vergessen – das Gurtband. Unsere Qualitätssysteme weisen nur 4% Gurtbanddehnung auf. Weniger Dehnung ist rationeller, weil die Zurrgurten weniger häufig nachgespannt werden müssen. Ausserdem verfügt unser gelbes Premium-Gurtband eine verschleissreduzierende Webkante.

Tension Force Indicator

Mit dem TFI können Sie die beim Niederzurren in das Zurrgurtensystem eingebrachten Vorspannkräfte nachweisen und in die Berechnung der Ladungssicherung übernehmen.

Selbstsichernder Ratschenhebel

Für maximale Sicherheit beim Zurren hat Spanset® den selbstsichernden Ratschenhebel entwickelt. Beim Zurren zieht man den integrierten Funktionsschieber. Schliesst man die Ratsche, rastet er automatisch in der Sicherungsposition ein. Ein unbeabsichtigtes Öffnen der Ratsche im Fahrbetrieb ist dadurch wirksam ausgeschlossen - selbst bei stärksten Vibrationen und Rüttelbewegungen.

Epoxidharzbeschichtung

Wir legen grössten Wert auf Qualität in jedem Einzelteil. Die Ratschen werden erst verzinkt, dann chromatiert und mit einer schlagfesten Epoxidharzbeschichtung überzogen. Die Ratsche ist damit zusätzlich vor Rostbildung geschützt.

Robustes Schutzschlauchlabel

Neben der ausreissfesten Verarbeitung durch Gewebeeinlage schützt ein robuster Folienschlauch die Be schriftung dauerhaft vor Abrieb und Verschmutzung. Das Schutzschlauchlabel ist ein grosser Vorteil, weil Zurrgurten mit fehlendem oder unlesbarem Label nicht eingesetzt werden dürfen.

Kompromisslose Qualität

Bei unserer ABS50 machen wir keine Kompromisse bei der Qualität. Wir verwenden ausschliesslich hochfesten, verzinkten Stahl und beschichten diesen mit Epoxidharz. Unser stufenweise lösbares ABS-System arbeitet mit robusten Doppelschiebern. Dank dieses Systems können Sie mehr als nur die Vorspannung kontrolliert lösen. Auch wenn die Ladung komplett gegen die Zurrgurte drück, lässt sich das SpanSet®-System immer noch kontrolliert lösen.

Verwendungsempfehlungen

Technische Produktinformationen

-

Oberflächenbeschichtung

Verzinkt -

Vorspannkraft STF

350 daN -

Vorspannkraft STF (mit TFI)

500 daN -

Normen

EN 12195-2 -

Temperaturbereich

-40° C to + 100° C -

Gurtband Breite B

50 mm -

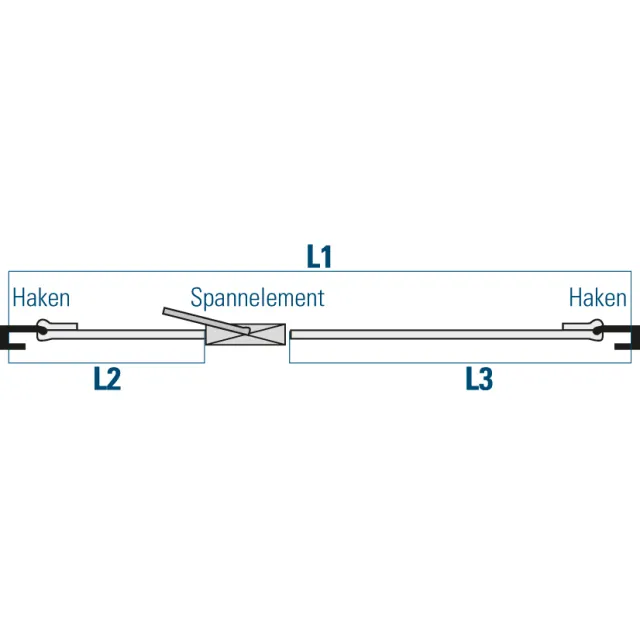

Abmessung L2

0.4 m -

Etikettenschutz

Ja -

Farbe

Gelb -

Gurtband Material

Polyester, thermofixiert und dehnungsarm <4% -

Tension Force Indicator (TFI)-Komponente

12345 -

Hauptmaterial

Polyester -

Ratschen-Typ

Druck -

Verbindungselement (VE)

29032 -

Tension Force Indicator (TFI)

Ja -

Zurrmittel Typ

Zweiteilig -

Verkaufseinheit (VE)

Stk -

Verpackungseinheit (VPE) Inhalt

1 -

Zurrkraft LC

2500 daN