PI 320

Transporting cars and trucks safely

Tunneling the friction loss

More flexibility when securing cars and trucks on vans. This is what SpanSet promises with a revised and expanded range of lashing straps, ratchets, strap controllers and hooks. The specialist for load securing from Übach-Palenberg combines the components in a "construction kit" from which the user can assemble the lashing system suitable for his requirements.

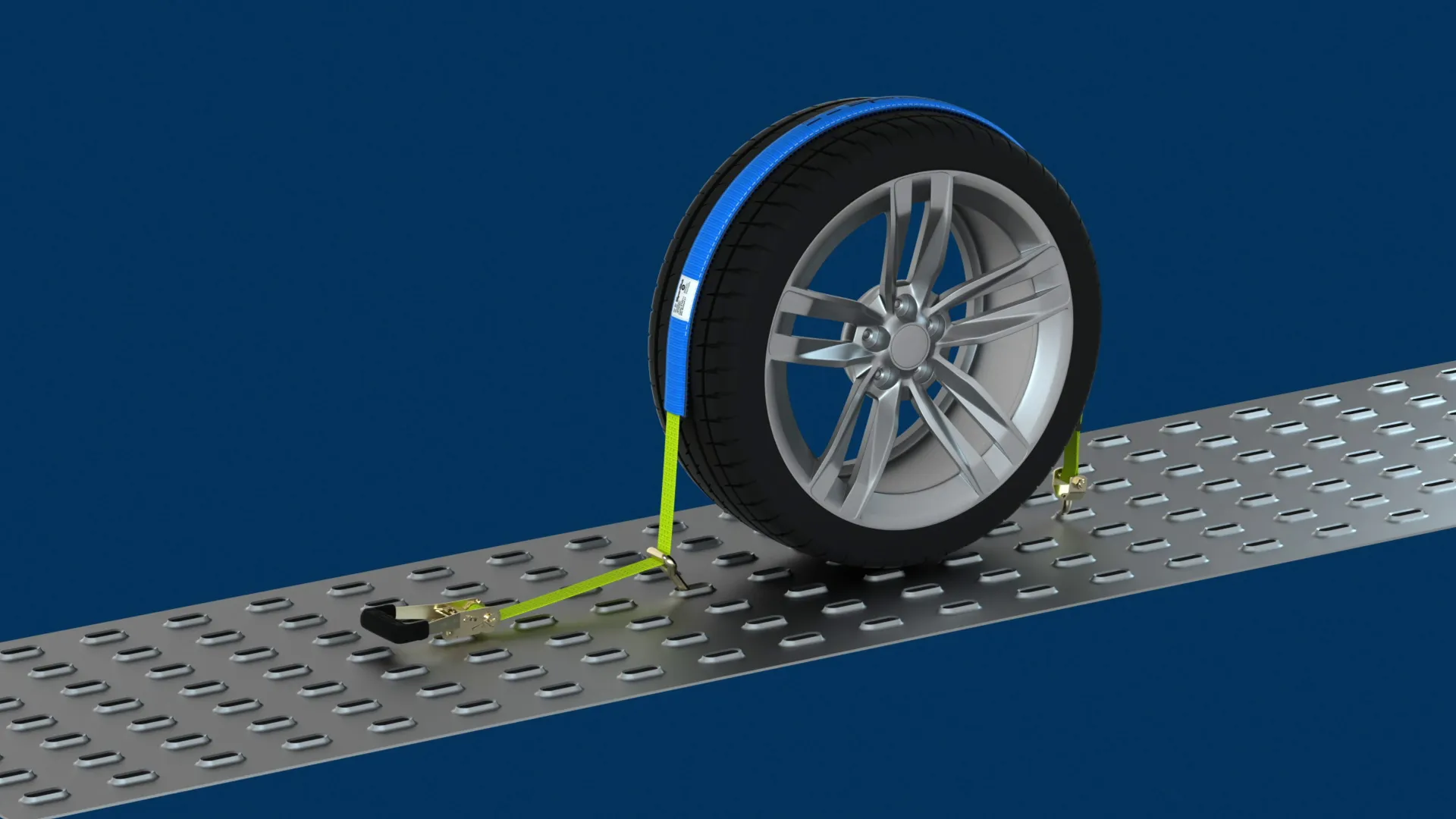

SpanSet distinguishes between two systems for securing cars and trucks: Carfix and Truckfix. Both use a tunnel-shaped sewn strap controller. This tunnel design reduces friction and allows the lashing strap to slide through the controller's tubular sleeve with less resistance during tensioning. The Carfix controller and its counterpart for trucks are suitable for almost all common car and truck tire sizes and are also manufactured to customer-specific length specifications.

Friction reduced, efficiency increased

Carfix uses 35 millimeter wide lashing straps with a lashing capacity of 1,500 daN (decanewtons). Truckfix uses 50 millimeter wide belts and achieves a lashing capacity of 2,500 daN. For both belt designs, the elongation capacity is less than four percent according to VDI Guideline 2700 Sheets 8.1 and 8.2.

An important indication of the relatively "smooth" interaction between the lashing strap and the controller is the high efficiency factor (ETA). In this specific case, it expresses the ratio of "pretensioning force in front of the controller" and "pretensioning force behind the controller". In other words, it is a question of how much of the force generated by the tensioning element reaches the opposite side of the wheel. For CarFix CT35 and TruckFix CT50Plus, the value is over 0.5 . This has been tested and certified by TÜV Süd. "TruckFix only achieves this outstanding result because we have provided its belt controller with a special sliding layer on the inside," says Ingo Burbach, who was in charge of the relaunch. Carfix CT35Plus even manages 0.7 with the sliding layer.

Checking the preload by visual inspection

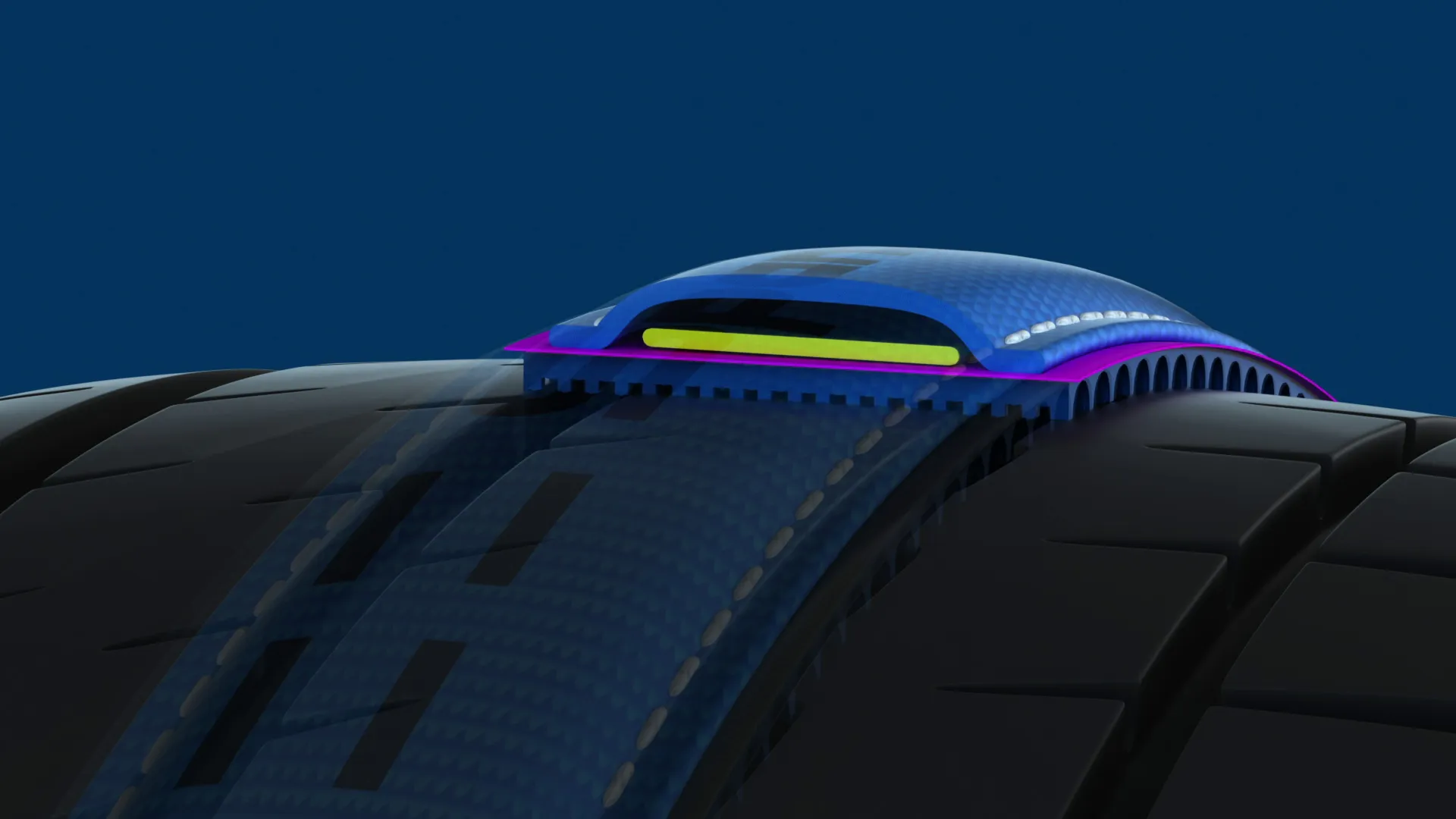

The system has increased its pretensioning force. Carfix reaches 330 daN and Truckfix 500 daN. A Tension Force Indicator (TFI) has been developed for Carfix and is supplied on request. It indicates when the required value has been reached on the side opposite the tensioning element: its cavities then close in a clearly visible manner. The preload indicator gives the driver a safe feeling at the beginning of his tour and allows a quick check at the pit stop whether everything is still in the green zone.

Unique hooks for less damage to the road surface

SpanSet has enlarged its range of hooks for the three lashing strap fixation points in the van's deck plate. "Conventional swivel point hooks put a lot of stress on the perforated sheet at specific points and often damage it," says Burbach, explaining the reason for the innovations. "That's why new hooks were developed that distribute the occurring forces over a wide area." The result is a perforated plate that is subject to less stress and can therefore be used for longer.

The "Base Clamp" uses a fixing plate that fits under the track plate. The "Snake Hook" has a sinuous shape. As a result, it distributes the force better over the surface of the perforated plate. The same applies to the "Fortyfive Hook", which hooks into the perforated plate at a 45-degree angle (see illustrations ). All three SpanSet hooks are suitable for drive plates with slotted holes.

Freely combinable

Hooks and other components of CarFix and TruckFix can be combined with each other - in line with the modular principle. They comply with the latest specifications of the relevant regulations. As clamping elements, SpanSet offers ergonomic pressure ratchets with a long lever and wide handle. They can be combined with all the hook types mentioned. "Our aim is to offer the user a wide range of options from which he can put together the lashing system best suited to his purposes," says Burbach. On request, SpanSet also supplies straps and controllers with individual colors and printing according to customer specifications.

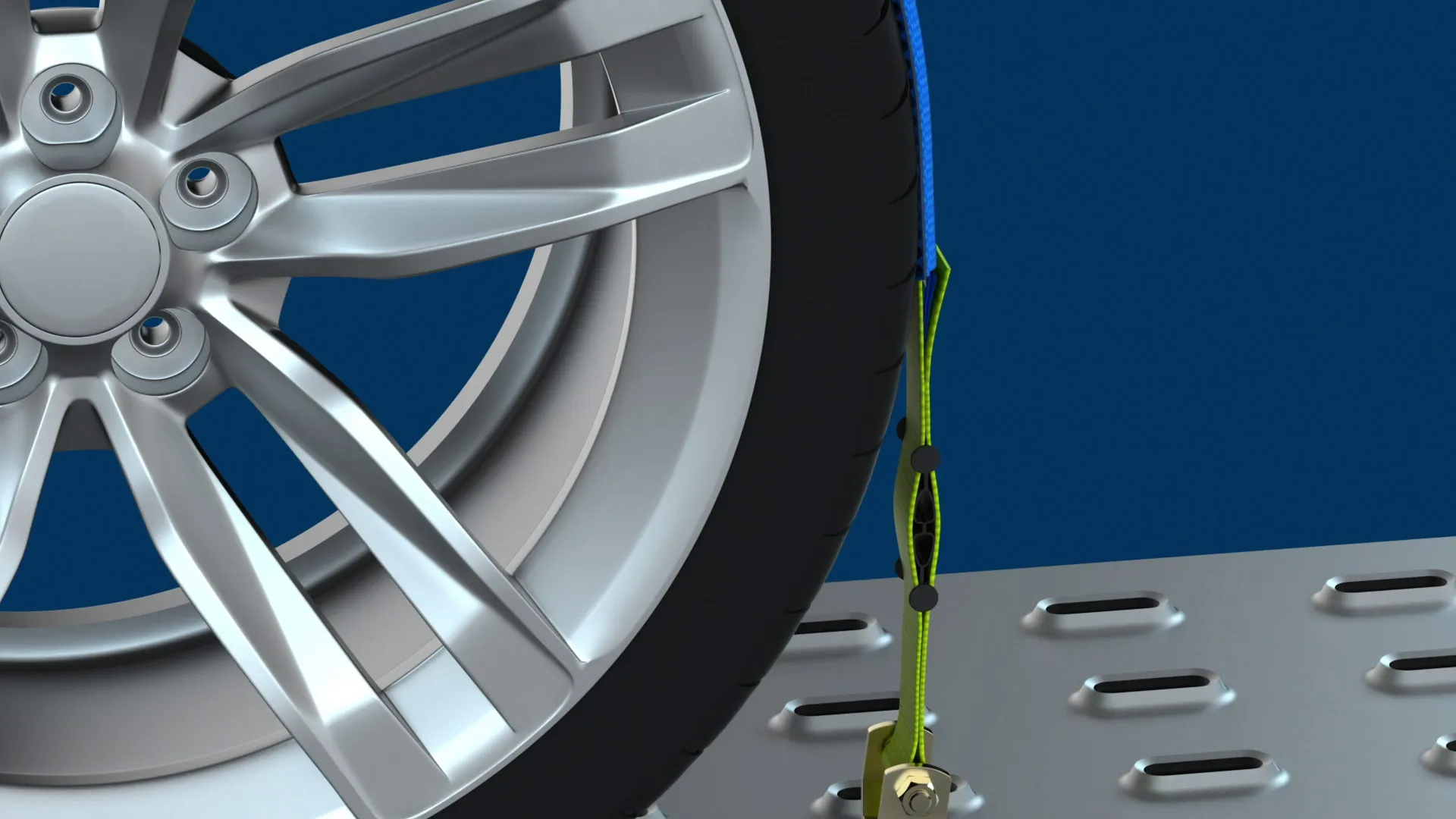

Fig. 1 SpanSet has fundamentally revised its system for safe car and truck transport.

Fig.2 and 3: The lashing strap (gray) slips through the tunnel-shaped sewn strap controller with little friction. The efficiency (ETA) reaches at least the value 0.7 (70 percent).

Fig.6: The Base Clamp (left) and the Forty-Five Hook lie flat and protect the perforated plate.

Fig.7 and 8:The Tension Force Indicator (TFI) is integrated into the Carfix lashing: At the required pretensioning force, the hollow bodies close.