There is no expiration date for lashing straps, but…

Question: How many years is a lashing strap for load securing (see illustration 7) allowed to be used on motor vehicles, vehicle combinations, and trailers? Counter question: How long is a car allowed to participate in road traffic?

Answer to both questions: As long as the technical and safety-related requirements are demonstrably met. – There is a lot to consider on this topic. What you should know is explained in this guest article.

by Werner Glasen (SpanSet Deutschland GmbH)

1 Basics

Manufacturers are often asked whether tie-down straps for load securing have a minimum shelf life (MHD) or, like medications, even an expiration date. The answer is: No, there is none. Based on our experience, tie-down straps can be used for many years and sometimes even decades when used properly, stored correctly, and maintained well."[2]

This is good news in itself, as there is fundamentally nothing to prevent a long and thus sustainable use of tie-down straps. But caution! No one certifies a tie-down system with an unlimited lifespan.

Instead, the service life depends on the technical condition of the tie-down straps. In this regard, the relevant guidelines and standards, such as VDI 2700 and EN-12195, primarily place the responsibility on drivers, loaders, and entrepreneurs. Each of them is jointly responsible for answering the question of whether a tie-down strap can be used in a specific case or if it should be discarded.

2 Operating instructions

he manufacturer should provide practical instructions for the use and maintenance of every tie-down strap and tie-down system. Adhering to the operating manual should be a matter of course for every driver, loader, and entrepreneur.

2.1 Check before each use

A visual inspection must be carried out before each use of a lifting sling or round sling. This also applies explicitly before the first use.

If there is any doubt about the suitability for use, or if the labelling is lost or illegible, lifting slings and round slings must be taken out of service and inspected by an expert.[3] Examples of faults or damage that can affect the long-term safe use of lifting slings include transverse and longitudinal cuts, cuts and chafing on the selvedges, cuts caused by sewing stitches or loops. The same applies to round slings, where transverse or longitudinal cuts in the sheathing indicate possible damage to the load-bearing core[4].

2.2 Regular inspection by a ‘competent person’

In addition to the mandatory visual inspection before each use of a lifting sling or round sling, the operator (contractor) must carry out and document routine inspections by a ‘competent person’ (formerly: ‘expert’). This is usually done at least once a year.

EN 1492 describes the qualifications that a ‘competent person’ must have, including appropriate training, specialist knowledge and practical experience. EN ISO 9002:1994 contains guidelines for training[5].

3 Labelling, marking and documentation requirements

All lifting slings and round slings must have a product label permanently attached to them. It must contain the following information, among other things: Traceability code (e.g. for recalls), date of manufacture, manufacturer's name, load capacity (see Figure 1).

The commissioning of a round sling or lifting strap must be documented in a digital database or on a file card. The same applies to the regular inspections by a ‘competent person’ (see point 2.2).

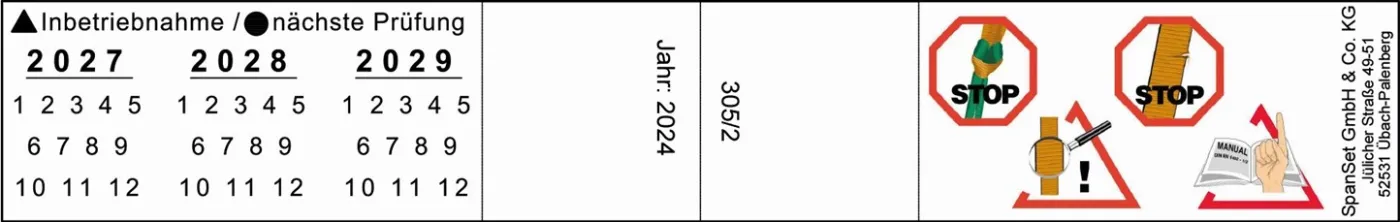

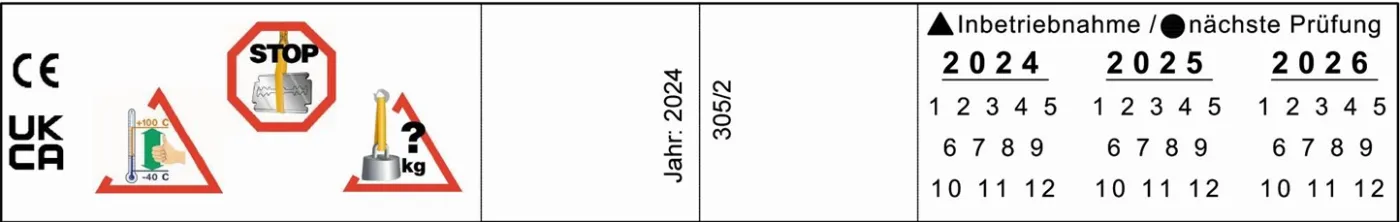

SpanSet Germany provides lifting slings and round slings with an additional label (see Figures 2, 3 and 5). This label is not mandatory, but has proven to be extremely helpful in practice. The user can mark the commissioning and the first six annual inspections with a waterproof pen. Important: This is additional and voluntary documentation. Labelling the additional label does not release the operator from the documentation obligation described above.

The date of manufacture on the label often triggers questions about the supposed ‘best before date’. This is also because there is sometimes a long period of time between production and first use. The following applies here: If the lifting sling or round sling has been stored in accordance with the manufacturer's instructions, the user will have a new product when it is put into operation - even many months after manufacture.

4 Maintenance and repair

In the operating instructions, repairs are usually only permitted by the manufacturer or a person authorised by the manufacturer. EN1492 states that repairs to the slings (see Figure 6) must never be carried out by the user[6].

5 Operating instructions

The manufacturer must provide practical instructions for the use and care of each lifting sling and round sling. Compliance with the operating instructions should be a matter of course for every user and contractor. The manufacturer must supply the operating instructions in paper form. From 2027, the new EU Machinery Directive will replace the Machinery Directive and allow digital operating instructions for textile slings such as round slings and lifting slings. Good for the environment and up-to-date for users and manufacturers alike.

6 Concluding remark

The fact remains: There is no expiry date for lifting slings and round slings. But a sling may only ever be used under certain conditions and only for its intended purpose. It is crucial that it is in perfect condition in terms of safety. This includes the presence of a clearly legible product label. In case of doubt, I recommend consulting the manufacturer or another professionally qualified person. Please always note: The absence of a best-before date does not mean that lifting slings and round slings can be used indefinitely without further ado (see Figure 4).

The author Werner Glasen has held various positions at SpanSet Deutschland GmbH & Co. KG (Übach-Palenberg) since 1991. More than 20 years ago, he took over the management of product management, sales and marketing.

Footnotes:

[1] Best before date

[2] See Textile slings - Safety - Part 1: Flat woven slings of man-made fibres for general purposes EN 1492-1:2000+A1:2008 page 9 (German version) and Textile slings - Safety - Part 2: Round slings of man-made fibres for general purposes EN 1492-2:2000+A1:2008 page 7 (German version).

[3] Cf. DIN EN 1492-1:2009-05 EN 1492-1:2000+A1:2008 (D), page 31 and round slings made of man-made fibres for general purposes DIN EN 1492-2:2009-05 EN 1492-2:2000+A1:2008 (D), page 23

[4] Cf. DIN EN 1492-1:2009-05 EN 1492-1:2000+A1:2008 (D), page 31 and round slings made of man-made fibres for general purposes DIN EN 1492-2:2009-05 EN 1492-2:2000+A1:2008 (D), page 23

[5] Cf. DIN EN 1492-2:2009-05 EN 1492-2:2000+A1:2008 (D), 3.15 Specialist, page 7

[6] Cf. DIN EN 1492-1:2009-05 EN 1492-1:2000+A1:2008 (D), 3.15 Expert, page 35

Fig. 1: Product label with year of manufacture and traceability code as barcode and number sequence

Fig. 2: SpanSet additional label (front). The month of commissioning is marked with a triangle. A dot indicates when the next test is due

Fig. 3: SpanSet additional label (reverse)

4: Life cycle of textile slings (lifting slings and round slings)

Fig. 5: Sewing the additional label (Fig. 2 and Fig. 3) together with the product label (Fig. 1) to the round sling. The additional label is used for labelling and documentation, among other things

Fig. 6: As described in the text (Section 4), the manufacturer SpanSet carries out repairs and maintenance on round slings

Abb.7: Anwendungsbeispiel einer von SpanSet produzierten Rundschlinge mit einer Tragfähigkeit von 20.000 kg