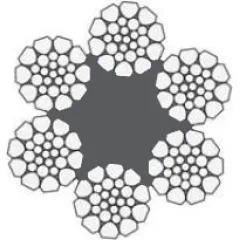

Compacted 6x26

Compacted 6x26

Specifically produced for ultimate wear resistance

- Superior quality galvanization for extra life

- Petroleum based lubricant for superior corrosion resistance

- Unique Identification Tag symbolises usage of original Usha Martin product

- Customised coloured strand in case of customer requirements

- Polypropylene core for flexibility wherever required

- Steel core for increased strength

- Greater resistance to crushing at crossover points

Please contact customer service for purchase or more information

All wire rope that we supply are only high quality and certified products according to International Standard of BS EN 12385, API Spec 9A, ISO 2408 and SNI.

These wire Rope are manufactured by a company that has ISO 9001:2015 certification and also have 3rd party certification from ABS, DNV-GL and Lloyds.

- Greater resistance to interference at the drum

- Sample from each production batch is tested in order to conform completely with customer specifications

- Increased abrasion resistance resulting from the unique compaction process

- High fatigue life due to compaction

Recommendations for Use

Do not use damaged wire ropes and slings with defects, such as wire breaks, bulges, bruises, kinks, severed core, heavy wear, rust damage or others.

Do not exceed the specified load carrying capacity (WLL).

Do not strike at a tilt angle exceeding 60°.

Do not use wire ropes with broken strands.

Do not use in contact with chemicals.

Sling ropes may only be used for lifting and transporting loads and only by instructed persons. The regulation on the safe use of cranes (Crane Regulation) must be observed without fail (Suva-Form.1420. d).

Product downloads and manuals

Datasheet

Download

Download