ABOUT US

SpanSet has been manufacturing quality synthetic products globally for over 50 years. The company’s vast experience in webbing-based products provided the perfect background to develop the innovative range of height safety equipment in evidence today. This evolved from the introduction of the first Euro-style, lightweight harness, which was a dramatic departure from the American-influenced heavy and cumbersome harnesses. From our best selling ERGO and ERGOiplus ranges through to our solution ranges for heat, corrosive, and high wear applications we always offer genuine value to our end user customers. The range covers all applications from fall arrest and work positioning to rope access and the Gotcha™ rescue range.

SpanSet continues to live up to its international heritage of innovations in design with new products and services. The latest developments enable us to push beyond the basic Australian Standards for design in Height Safety equipment.

How our inventions became the norm...

The SpanSet products, with their load capacity, have gained such a good reputation around the world that international safety standards have been orientated to them. SpanSet has significantly influenced the development of standards for Height Safety equipment. This is how something becomes the norm: by setting a standard and doing so repeatedly for more than 50 years.

... and how our norm influenced new inventions.

This also means that we are often called on during the development of a new product (after all, it will eventually be transported by our load restraints) and increasingly offer support as a partner for safety training and consultation.

This is how SpanSet went from a small ribbon weaving company to an international forerunner for Height Safety, Transportation, and Safety – through exceptional performance and recognition.

SPANSET HISTORY

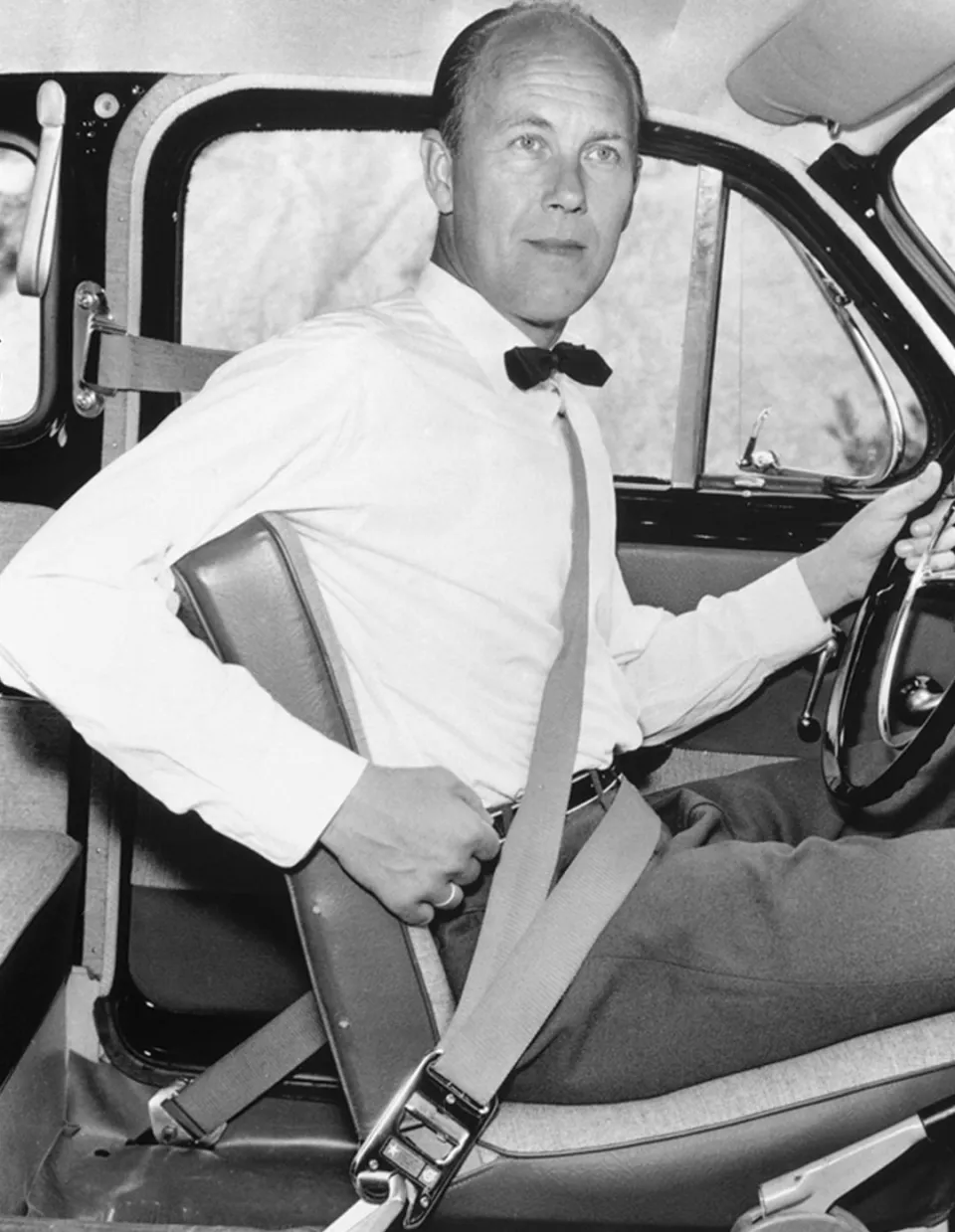

How the safety belt became a safety standard.

It is hard to imagine that a few decades ago, most cars were shipped without seat belts. In other respects too, little attention was paid to accident prevention at that time, and so many collisions from which today one would emerge unscathed, had fatal consequences.

In order to counter this, the Swedish car company Volvo approached two small Swedish ribbon weaving companies AB Textilkonst and Klippan at the end of the 1950s, with instructions to develop a safety belt for its vehicles.

Volvo was already building very sturdy cars that withstood the harsh Swedish winters and other tests, but it wanted to continue to improve the safety of the occupants.

Together with Volvo engineers, Klippan developed the first car safety belt in the world, made of high-strength fabric ribbon. It was installed in models Amazon and 544 for the 1st time in 1959 and caused a lot of astonishment in the public, while also ensuring an enduring image of Swedish inventions as both pioneering and durable.

How We Replaced Ropes and Chains

The car safety belt was a great success, and soon other manufacturers had also installed it. Thanks to the great demand, Erik Ehnimb, co-owner of Klippan, was able to found the SpanSet company in Malmö in 1966.

The ribbons produced by SpanSet were quickly and enthusiastically employed in many other areas, where up to that point chains and wire ropes had been used, as in the case of the transport of paper. The customers appreciated the enormous load-bearing capacity of the new lashing and lifting belts.

In 1967, Mr. Ehnimb founded SpanSet AG in Hombrechtikon in the Zurich highlands and additional companies in Germany, Italy, France and England. Later, companies in Asia, America and Australia were added, thus forming a global distribution network.