The Importance of K3 Training in Preventing Workplace Incidents

K3 training and certification are often seen as mere formalities. However, this case study demonstrates the critical importance of training in preventing significant losses, both in terms of lives and company operations.

Did you know, friends at SpanSet, that on February 7, 2025, there was an accident in the Bekasi area? In this incident, two workers, identified as T and D, tragically lost their lives after falling from a gondola while cleaning windows on the 8th floor of an apartment building.

Workplace Accident Data in Indonesia

According to a report from Detiknews, "The gondola had four sling ropes. Each of the four sling ropes consisted of two ropes for the machine to raise and lower the gondola and two safety ropes. The incident is suspected to have been triggered by a loose gondola sling rope, resulting in both workers falling from the gondola."

From this, it is clear that there are many gaps that need to be addressed to prevent such horrific accidents from occurring in the future. According to Satu Data Ketenagakerjaan, from January to August 2024, there were 278,564 recorded workplace accidents in Indonesia. This figure highlights the urgent need for improved implementation of safety protocols and stricter oversight by the government.

What Can Be Learned from This Incident?

Based on the data presented earlier, the rate of workplace accidents in Indonesia remains quite high. To prevent similar accidents from occurring, several lessons can be drawn:

Lack of Awareness and Understanding of K3

Many risky situations go unnoticed and are ignored, stemming from a lack of proper understanding of workplace safety, which leads to a lack of awareness of potential hazards.Therefore, K3 training plays a vital role in building awareness and equipping workers with the knowledge to identify and prevent risks in the workplace.

Recovery Processes That Require Time and Costs

When an incident occurs, the losses inevitably fall on the company, which must incur significant costs for compensation, equipment repairs, and project delays.Additionally, the physical and mental recovery of workers affected by accidents will take considerable time.

Prevention Steps and Incident Risks

Most workplace accidents can be avoided if companies and workers implement appropriate preventive measures. How? By conducting K3 training, workers can understand and recognize the risks associated with their jobs and follow K3 procedures according to standards.Here are some preventive steps that can be applied:

- Regular K3 Training: Provide routine training to ensure workers understand the latest safety standards.

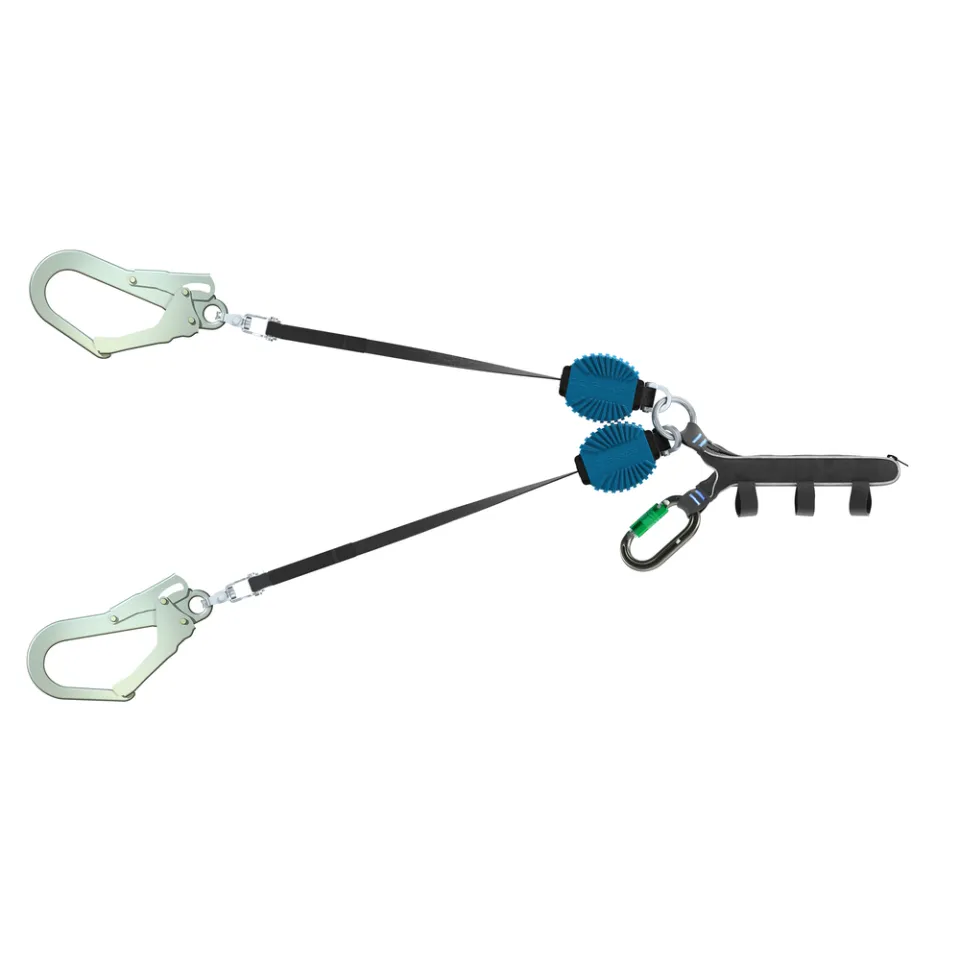

- Use of Personal Protective Equipment (PPE) as needed.

- Inspection and Maintenance of Work Equipment: Ensure that the tools used are safe and do not pose accident risks, requiring regular checks.

- Implementation of Strict Standard Operating Procedures (SOPs).

- Safety Monitoring and Evaluation: Conduct regular safety audits to ensure that every aspect of safety is properly implemented.

Conversely, if these measures are neglected, the risk of incidents will increase dramatically. This is why training is mandatory for every worker, as many may not know how to avoid hazards, operate tools safely, or respond correctly to emergencies.

The Importance of K3 Training for Safety at Heights

The incident involving the two workers who fell from the gondola while cleaning windows highlights the importance of Occupational Health and Safety (K3) training.

Training is essential for workers to understand the real risks in the field, enabling them to identify potential hazards and implement appropriate preventive measures.

Let’s work together to maintain safety in the workplace and deepen our knowledge about safety at heights with us. Friends at SpanSet can participate in TKBT 1, TKBT 2, and TKPK training at SpanSet Indonesia. For more information and registration, please consult via email at sales@spanset.co.id or training@spanset.co.id.