Australia's Trusted Source for

Safe and Reliable Lifting Products.

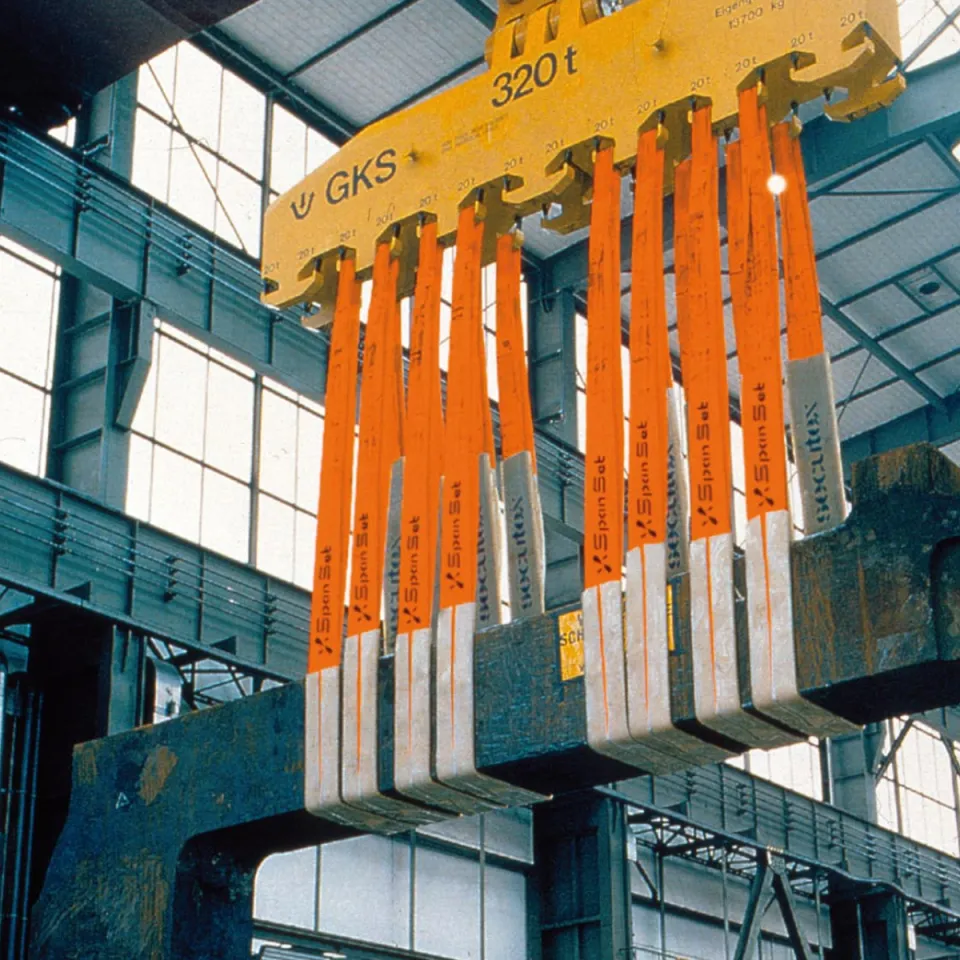

Explore our wide range of round slings, flat slings, lifting protections, and more.

SpanSet Australia: Engineered Lifting Solutions for Safety and Performance

At SpanSet Australia, we're dedicated to providing high-quality, reliable lifting solutions designed to meet the rigorous demands of Australian industries. Our comprehensive range of products is engineered for safety, durability, and optimal performance, ensuring you can lift with confidence.

Not sure which lifting product

is the right one for you?

Get in touch with our team today!

Our Lifting Equipment is Designed, Manufactured & Tested

in Australia.

Emu Plains, SYDNEY

Scroll through our Extensive Range of Lifting Solutions

Frequently Asked Questions (FAQ)

- Lifting with SpanSet

General Questions

What types of lifting products does SpanSet Australia offer?

SpanSet Australia offers a comprehensive range of lifting products designed for various industrial and commercial applications. This includes, but is not limited to, round slings, flat slings, lifting nets, lifting clamps, and steel accessories and components.

Are SpanSet lifting products compliant with Australian Standards?

Absolutely. All SpanSet lifting products are designed, manufactured, tested, and certified to meet or exceed relevant Australian Standards, such as AS 1353.1 (Flat Synthetic Webbing Slings) and AS 4497 (Round Slings). Safety and compliance are at the core of our manufacturing process.

Where are SpanSet lifting products manufactured?

We are proud to be an Australian manufacturer. Our head office and purpose-built manufacturing facility are located in Emu Plains, Western Sydney, New South Wales. We prioritise using Australian-made webbing and components whenever possible.

How do I choose the right lifting product for my specific application?

Choosing the correct lifting product depends on several factors, including the weight and nature of the load, the lifting method, and environmental conditions. We recommend consulting our product specifications and, if unsure, contacting our expert team for guidance. Our technical data sheets provide detailed information on each product.

Do you offer training on the safe use of your lifting equipment?

Yes, SpanSet Australia is a registered training organisation (RTO ID: 91173) and offers a range of nationally accredited training courses, including those related to safe lifting operations and competent person practical inspection.

Questions about SpanSet Round Slings

What are the key advantages of using SpanSet Round Slings?

SpanSet Round Slings offer numerous benefits, including:

- Compliance: Fully compliant with Australian Standards AS 4497:2018.

- Durability: Manufactured with high-strength polyester fibres protected by a robust outer sleeve for extended service life. Our SupraPlus range features a 40% thicker sleeve for increased durability.

- Versatility: Ideal for choke lifting cylindrical objects and lifting smooth objects without damage.

Lightweight and Soft: Reduces manual handling injuries and offers excellent strength-to-weight ratio. - Variable Load Bearing Point: Ensures more even wear for prolonged use.

- Clear Identification: Colour-coded outer covers with woven-in weight stripe markings and Tuff Tags for easy identification of capacity.

What is the safety factor for SpanSet Round Slings?

Our round slings typically have a safety factor of 7:1, ensuring a significant margin of safety beyond the stated Working Load Limit (WLL).

Can SpanSet Round Slings be used in specific environments (e.g., with chemicals, extreme temperatures)

SpanSet polyester lifting slings offer broad chemical resistance and excellent UV performance. However, use with aggressive substances or in extreme temperatures should always be considered. We recommend consulting the specific product's technical data sheet or contacting SpanSet for detailed information on chemical resistance and temperature ranges.

How often should I inspect my SpanSet lifting equipment?

All lifting equipment, including SpanSet round slings, should be inspected by a competent person at least every six months, or more frequently depending on environmental conditions and usage. Any equipment deemed unsuitable for continued use must be immediately removed from service. SpanSet offers competent person training for inspections.