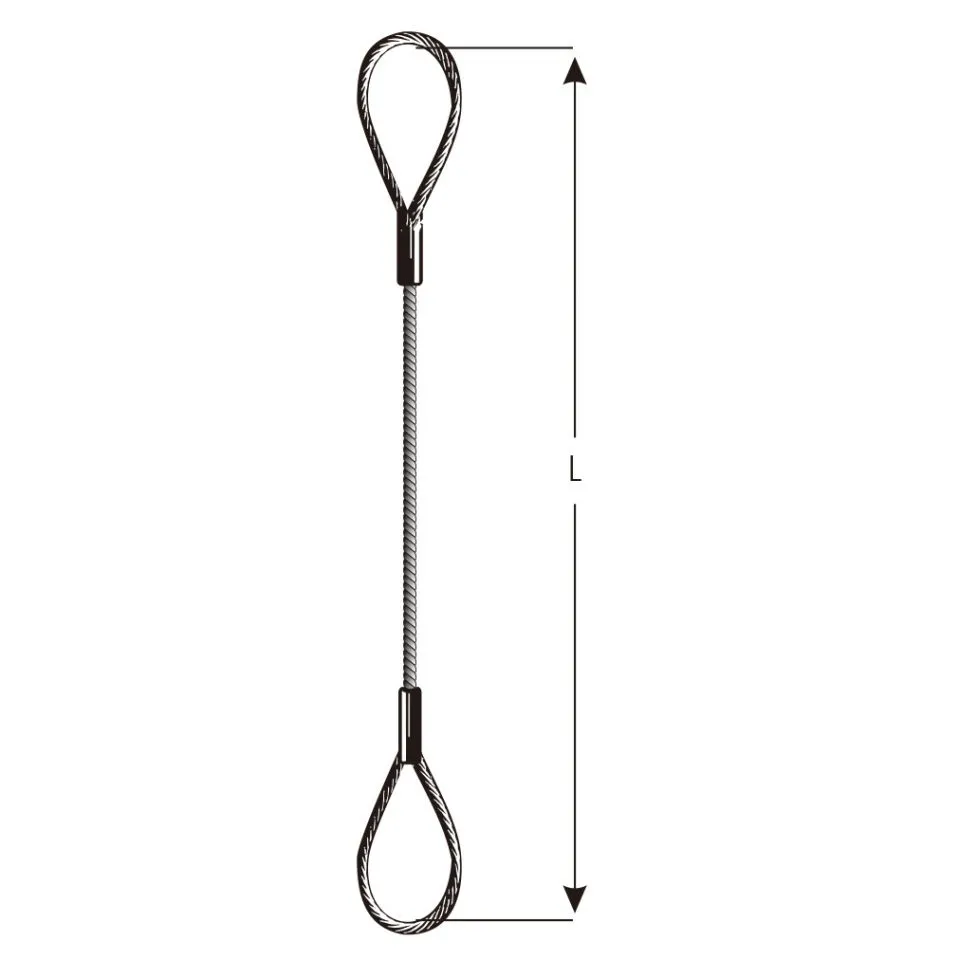

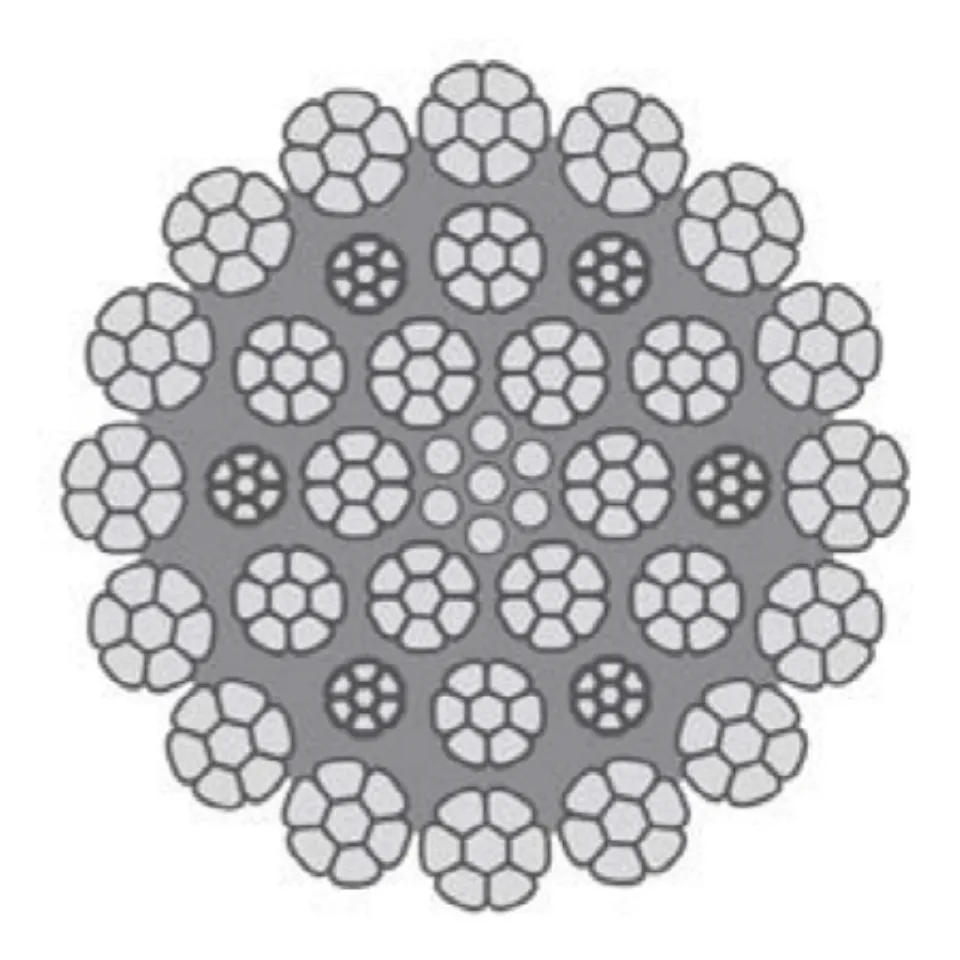

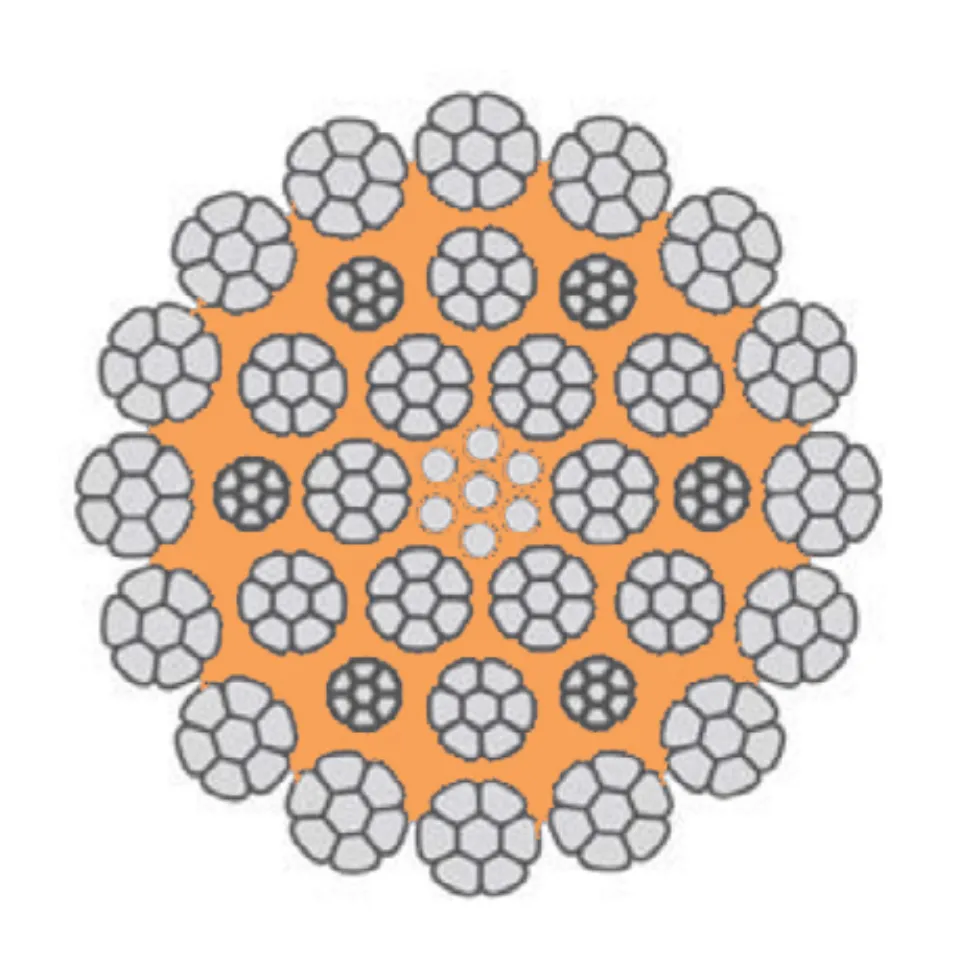

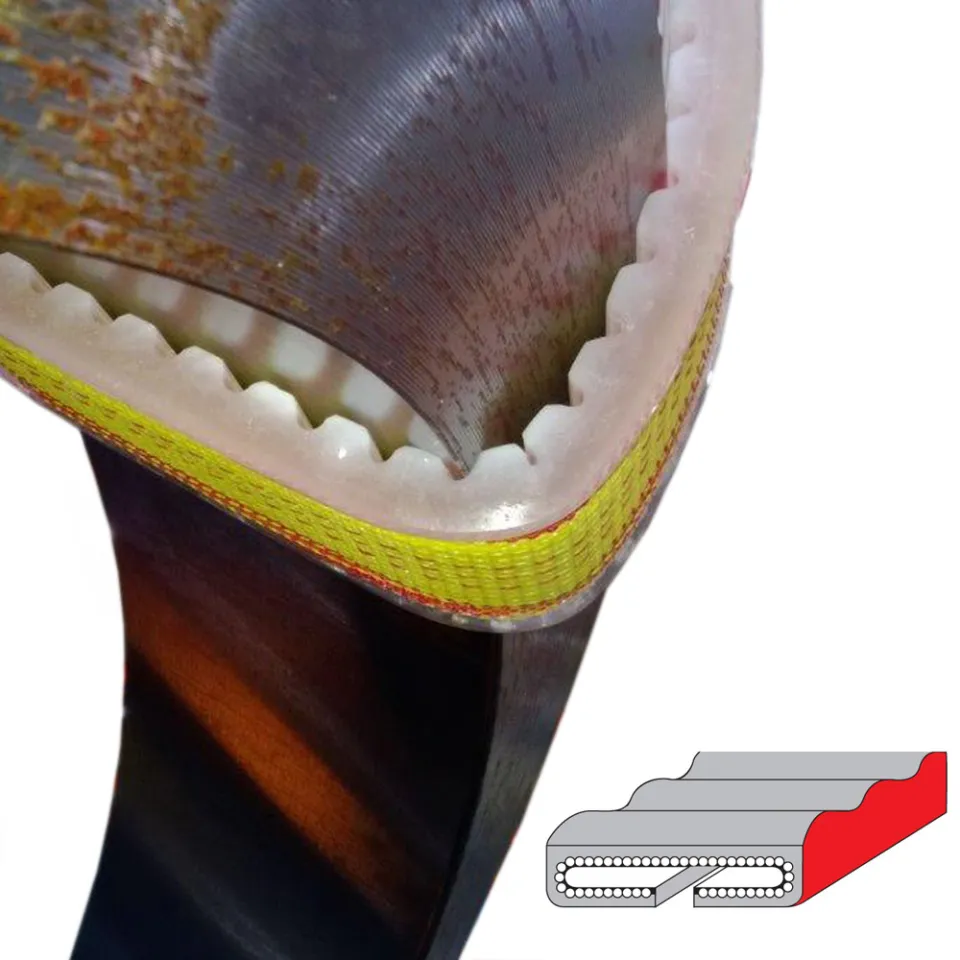

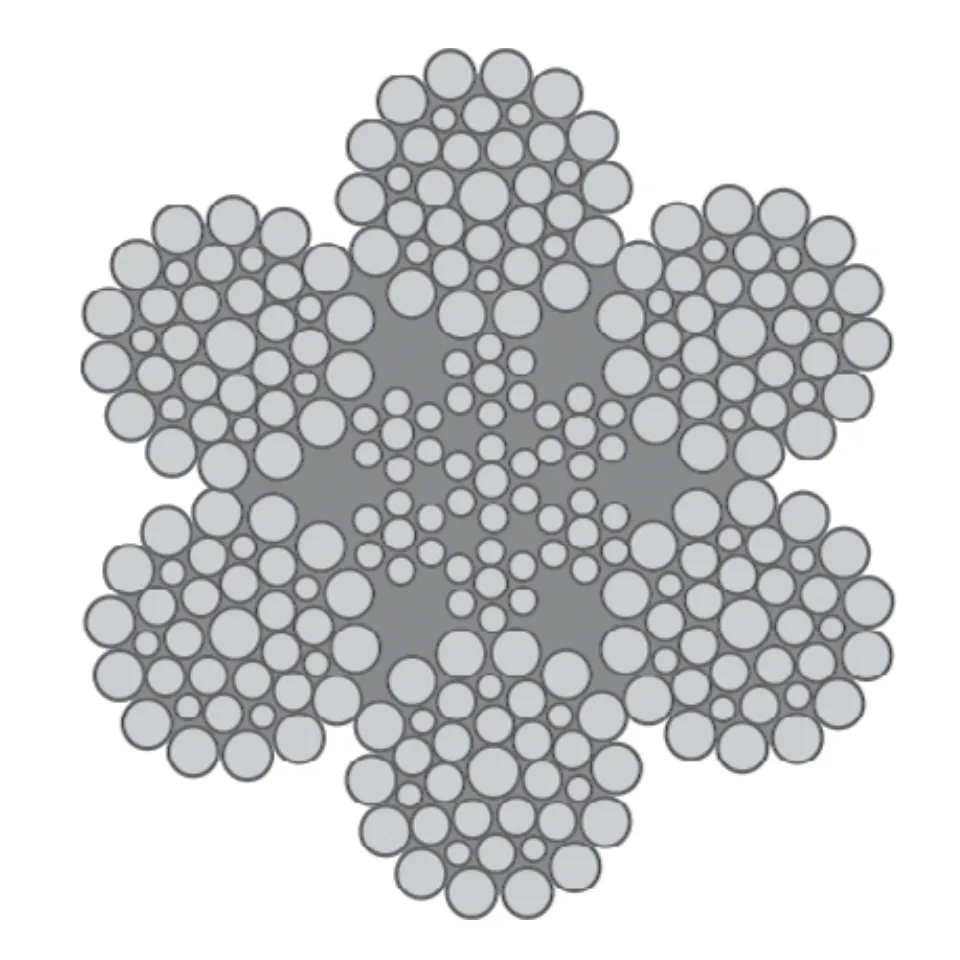

Dalam dunia rigging dan pengangkatan beban, wire rope menjadi komponen vital yang wajib selalu dalam kondisi prima. Namun, karena sifatnya yang terpapar tekanan dan gesekan saat digunakan, wire rope rentan mengalami keausan di area loop atau mata.

Untuk menjaga integritas dan memperpanjang umur pakai wire rope, penggunaan thimble menjadi best practice dalam industri. Yuk kita bahas lebih dalam apa itu thimble, fungsi utamanya, jenis-jenis yang tersedia, serta cara pemasangannya.

Apa Itu Thimble dalam Wire Rope ?

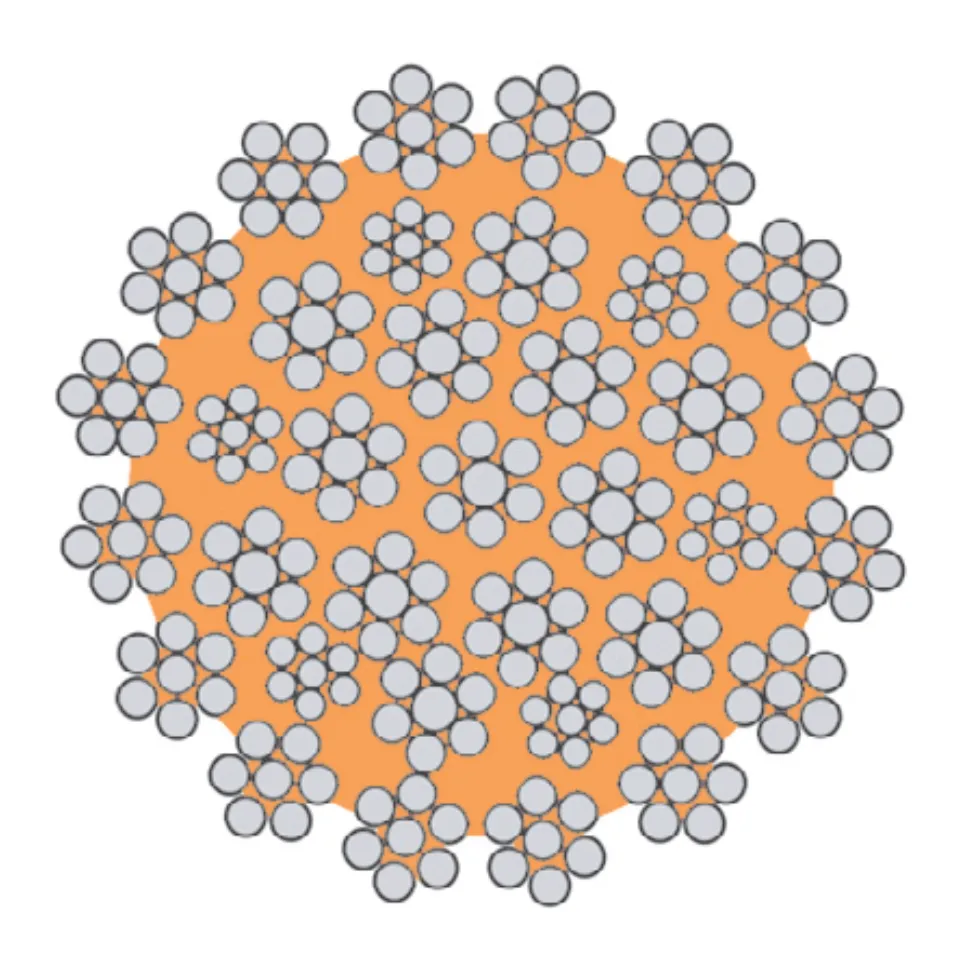

Thimble adalah komponen yang bentuknya mirip seperti cincin, terdapat lekukan yang dirancang khusus untuk ditempatkan di dalam loop pada wire rope. Fungsinya adalah untuk melindungi wire rope dari tekanan berlebih dan gesekan saat beban diangkat atau ditarik.

Dengan demikian, peran thimble menjaga bentuk loop tetap optimal dan mengurangi risiko kerusakan atau keausan dini pada wire rope.

Dalam berbagai aplikasi, terutama pada pengangkatan beban berat dan sistem rigging, penggunaan thimble dianggap menjadi salah satu langkah preventif untuk memastikan keselamatan operasional.

Materials Used to Manufacture Thimbles and Their Durability

The performance and service life of a thimble are greatly influenced by its material and manufacturing process. Thimbles can be made from various materials, each offering distinct characteristics and advantages tailored to specific application needs:

Carbon Steel

Thimbles made from carbon steel are highly popular due to their high tensile strength.

Carbon steel can withstand heavy loads and pressure, though it is susceptible to corrosion if not given special treatment (such as tempering or protective coating).

Galvanized Steel

With a zinc coating applied through galvanization, galvanized steel thimbles gain extra corrosion protection.

This material is ideal for humid environments or applications exposed to seawater, significantly enhancing durability.

Stainless Steel

Stainless steel offers extremely high resistance to corrosion and oxidation, making it ideal for marine, chemical, and other aggressive environments.

Although typically more expensive, its superior durability often makes it the best choice for critical applications.

Aluminum

Aluminum thimbles are used in applications that prioritize weight reduction without significantly sacrificing strength.

Aluminum is lighter than steel but has moderate strength, making it suitable for loads that are not extremely heavy.

Exploring Various Thimble Shapes and Their Uses in Wire Rope

As protectors of the wire rope loop, thimbles ensure the splice shape remains optimal without wear from abrasion. Various thimble designs have been developed to suit specific rigging applications. Here are the main types and their descriptions:

1. Standard Thimble

The most common type due to its simple design. It has a circular profile with a smooth groove that helps maintain loop integrity.

Application: Suitable for light to medium rigging tasks, such as general mooring and lifting, effectively reducing wire rope abrasion.

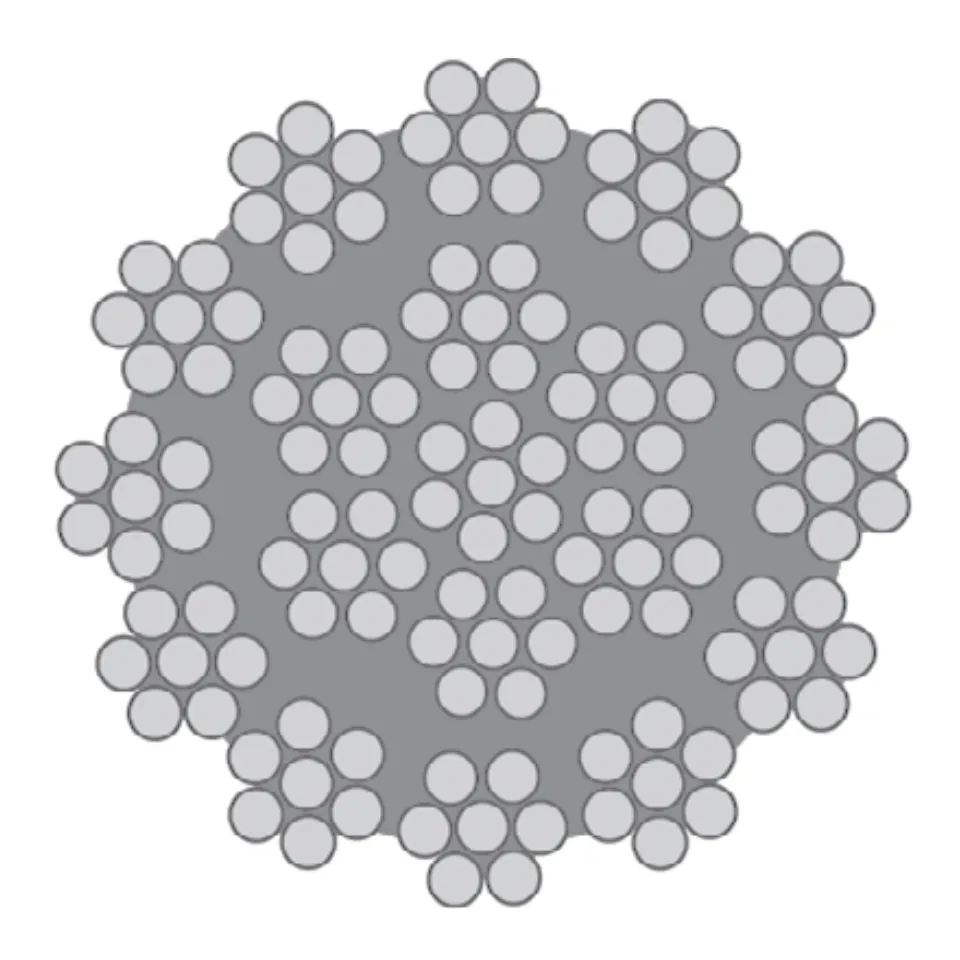

2. Heavy-Duty Thimble

Specifically engineered to withstand heavy loads with high durability.

Made from thicker steel and galvanized for extra strength.

Application: Ideal for construction, mining, and industrial lifting projects requiring optimal loop deformation protection.

3. Galvanized Thimble

Offers enhanced corrosion protection via a zinc coating. The steel body is zinc-plated to resist rust.

Application: Perfect for marine or outdoor rigging environments prone to corrosion.

4. Stainless Steel Thimble

Designed for maximum protection in extreme conditions.

Made from stainless steel for a clean, aesthetic finish and excellent corrosion and wear resistance.

Application: Used in marine, chemical, and food-processing industries where extra protection is required.

5. Aluminum Thimble

Provides a lightweight solution for applications where weight reduction is critical.

Aluminum construction is lighter than steel yet still offers sufficient strength.

Application: Suitable for transportation and aerospace industries where weight efficiency is paramount.

6. Reinforced Thimble

Built with additional structural elements for increased strength.

Features layered construction or welded joints to reinforce the thimble body.

Application: Used under extreme loads, such as crane rigging and heavy-duty construction lifting.

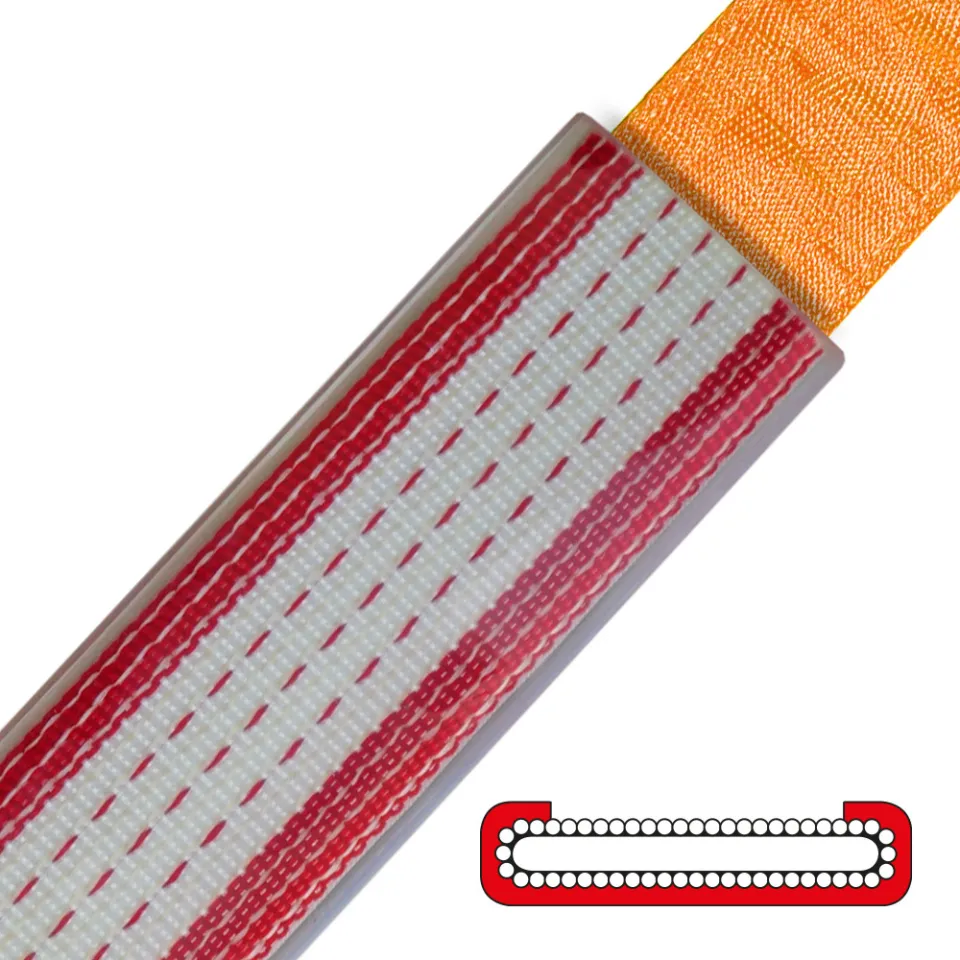

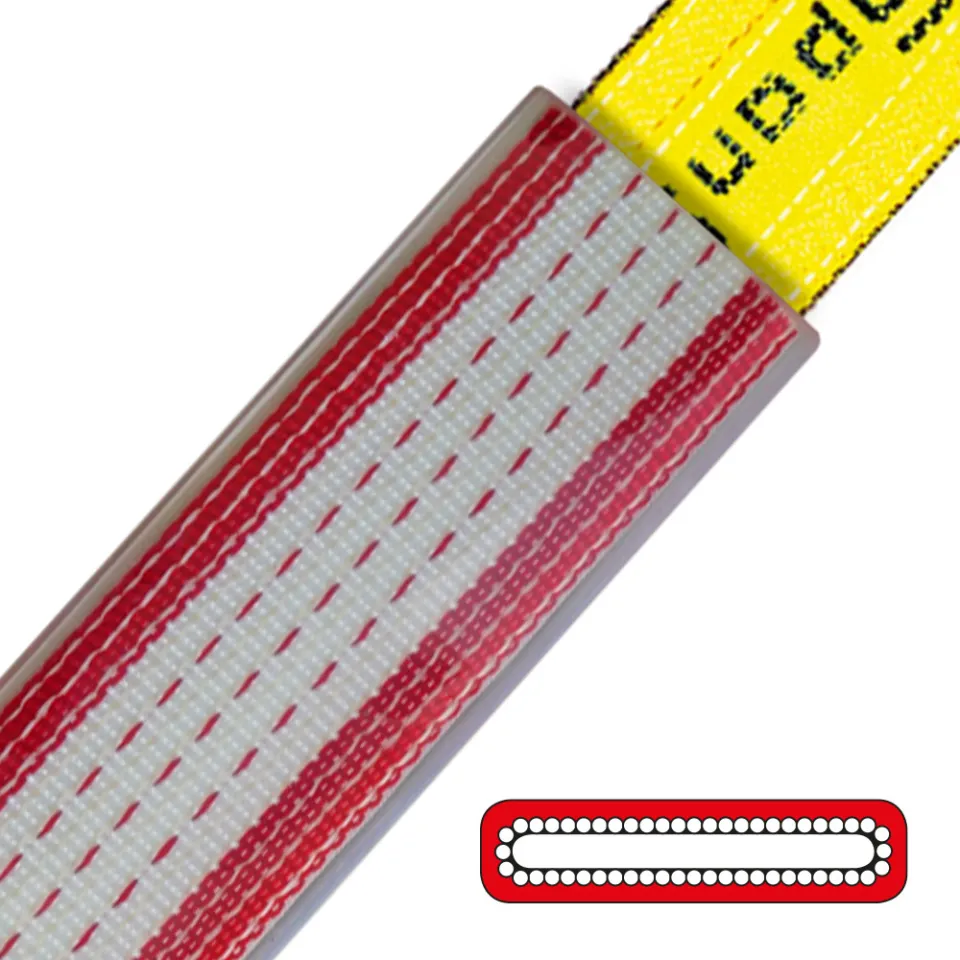

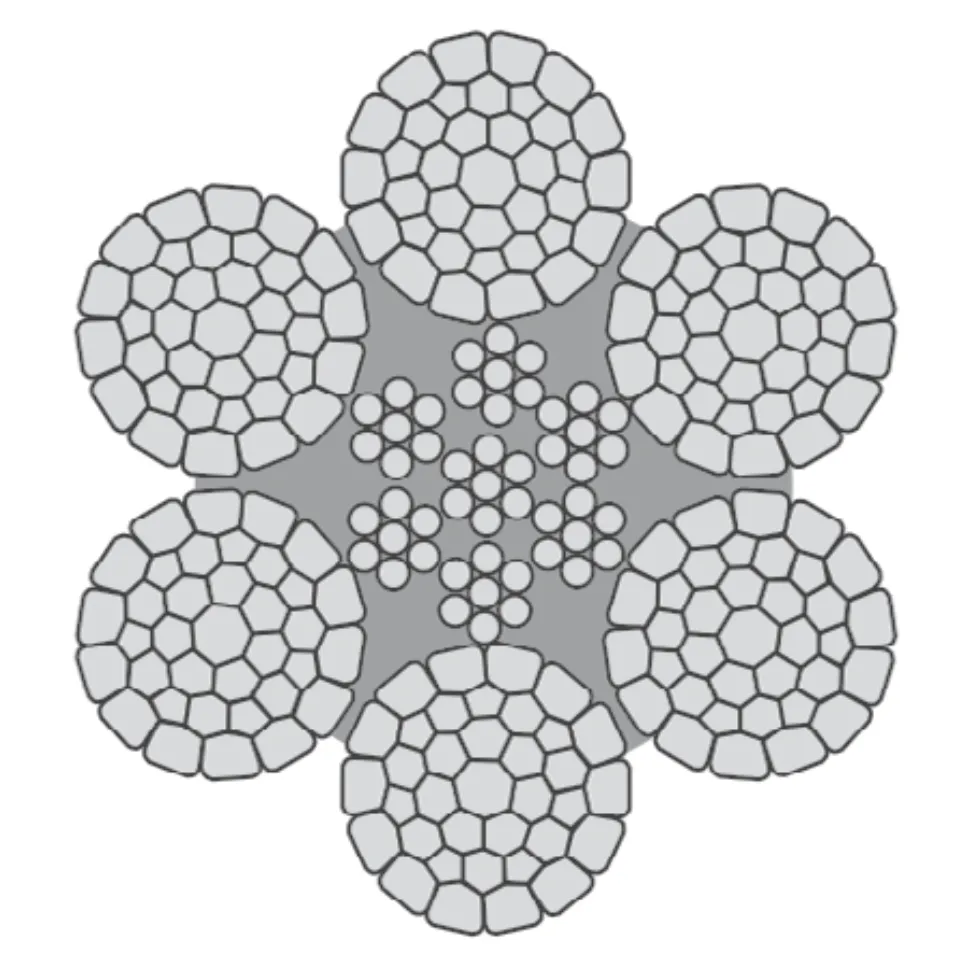

7. Solid Thimble

Maximizes strength and durability with a very robust material.

Manufactured from cast ductile iron known for its high structural strength.

Application: Ideal for boom or pendant crane applications where stability and strength are critical.

8. Solid DIN 3091 Thimble

Meets international standards for heavy-duty use. Made from mild steel per DIN 3091 and galvanized for corrosion protection.

Application: Commonly used in cranes and other heavy lifting systems requiring strict technical compliance.

9. Heavy-Duty Tube Thimble

Engineered for situations demanding extra resistance to pressure.

Features thicker walls to consistently withstand high pressure.

Application: Employed in heavy rigging for marine and construction sectors with demanding operational conditions.

10. Eye (Soft Eye) Thimble

Offers flexibility for applications requiring adjustable loops.

Designed so the wire rope loop can be resized without losing shape.

Application: Suitable for temporary splices or scenarios needing rapid rigging adjustments.

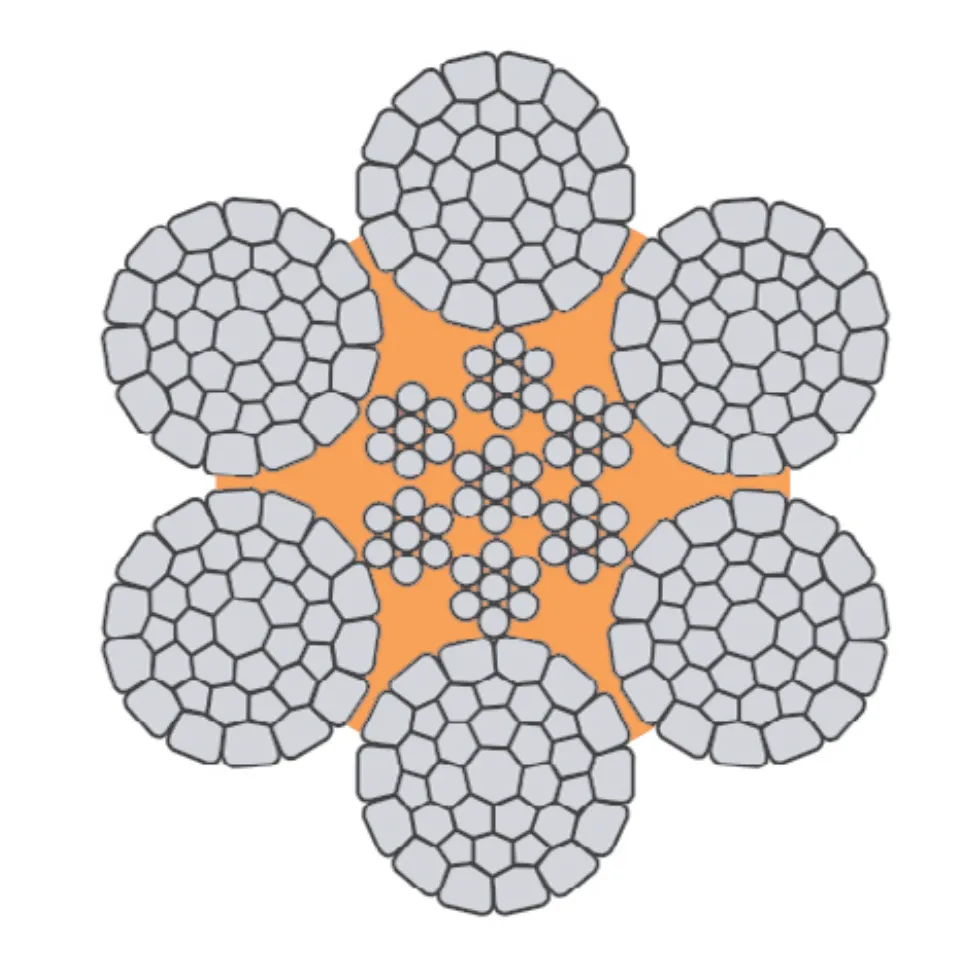

Thimbles in Different Working Environments

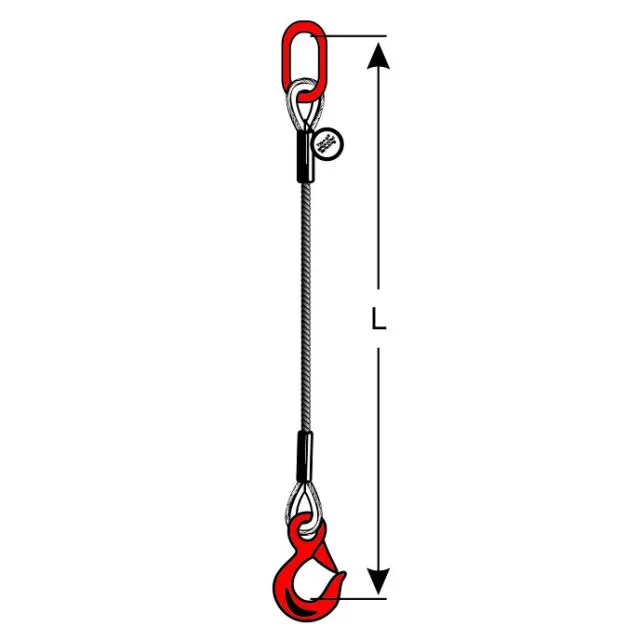

From offshore operations to use in heavy industrial settings, thimbles prove to be a critical element that helps distribute load evenly and protect the rope from excessive abrasion. Here are thimble applications in several key work environments:

Thimble Applications in Marine Rigging

In marine environments, thimbles play a vital role in supporting lifting operations and cargo handling at ports and on vessels. In marine rigging:

- Lifting & Cargo Handling: Thimbles are used when lifting containers, boats, or other heavy materials, ensuring the wire rope loop remains intact and resists wear even under dynamic loads.

- Mooring Line Securing: During ship mooring, thimbles help secure lines to fittings, reducing damage from repeated abrasion or overload.

- Mooring Operations: When a vessel is held by mooring lines, thimbles maintain the loop shape critical for load distribution, providing stability at the berth.

Thus, using thimbles in marine rigging not only improves lifting efficiency but also extends the service life of wire ropes exposed to harsh sea conditions.

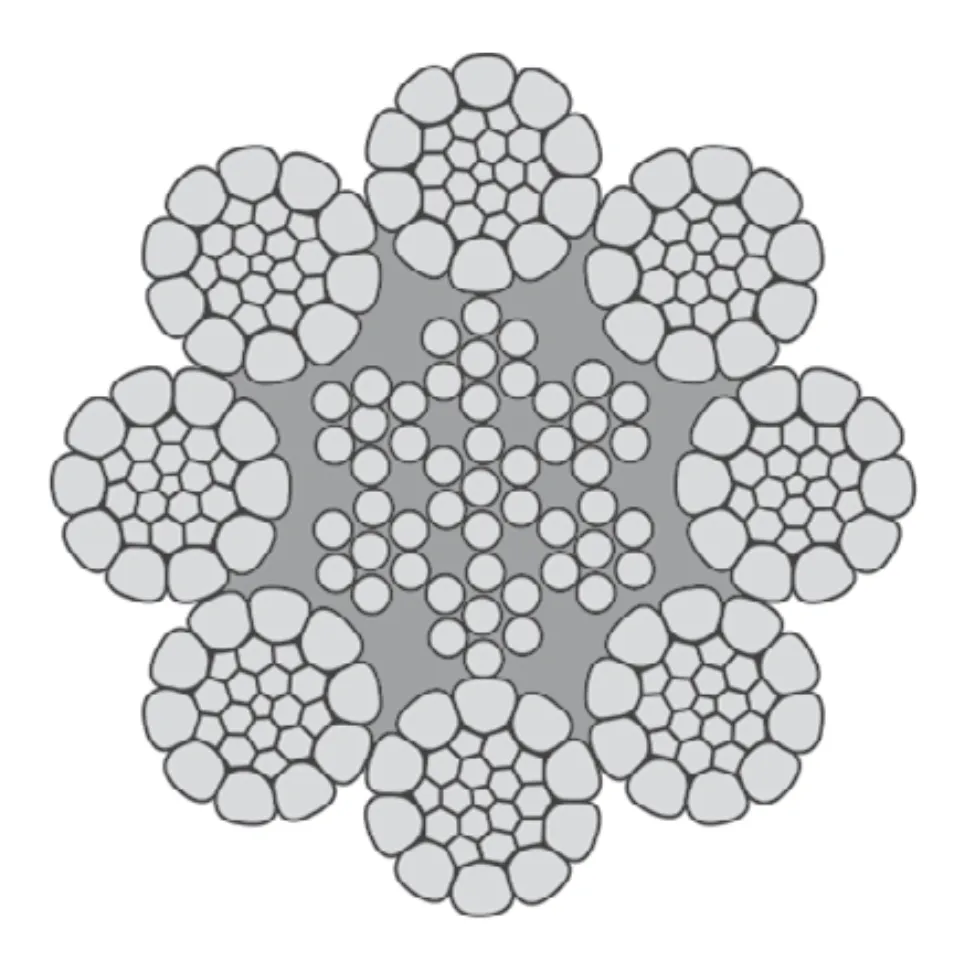

Thimble Use in Heavy and Industrial Loads

In industrial sectors—especially heavy-load applications—thimbles are essential to maintain the safety and integrity of rigging systems. Examples include:

- Building Construction & Material Lifting: Thimbles are used to lift materials such as concrete, timber, and metal. By keeping the loop round, thimbles distribute load evenly and prevent premature splice failure.

- Mining: In mining operations, thimbles protect the end of haul ropes when lifting and pulling heavy loads like coal and ore, reducing intense abrasion and preserving wire rope life.

- Oil & Gas Industry: At drilling sites and processing facilities, thimbles assist in lifting heavy equipment and securing harnesses and lifelines for safety.

Applying thimbles in industrial settings ensures rigging systems can safely handle heavy loads, support efficient lifting operations, and minimize accident risks.

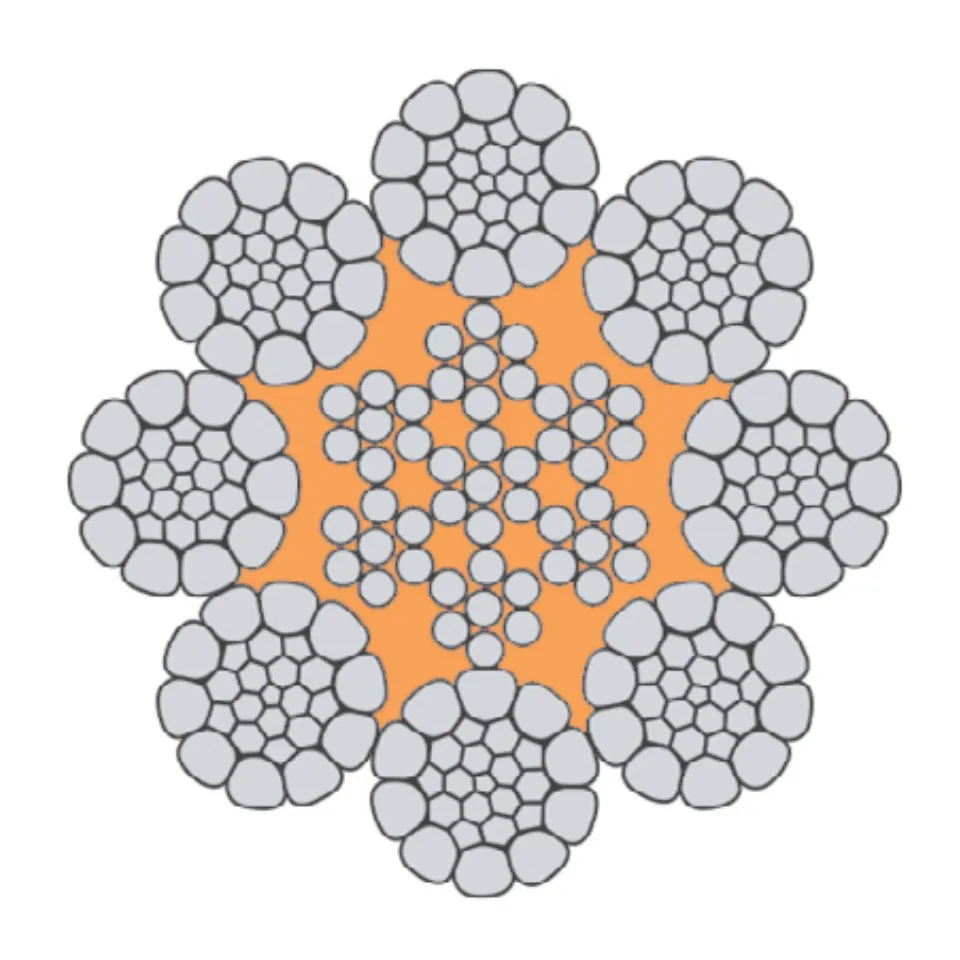

Thimble Durability in Corrosive Environments

Corrosive workplaces—such as coastal areas, ports, or chemical plants—demand thimbles with high resistance to oxidation and rust. Key aspects of thimble durability under corrosive conditions include:

- Superior Materials: Stainless steel or galvanized thimbles offer extra corrosion protection. These materials are ideal for humid, seawater-exposed, or chemically aggressive environments.

- Design & Coating: Zinc galvanizing provides an additional protective layer, and optimized groove design ensures even load distribution, reducing corrosion hotspots.

- Maintenance & Inspection: In corrosive settings, regular inspection and maintenance routines are crucial. High-corrosion resistance reduces replacement frequency.

Therefore, thimbles are engineered to resist corrosion, safeguarding wire rope performance in harsh environments and enhancing operational safety and efficiency where corrosion damage is prevalent.

Thimble Maintenance Tips for Longevity

Having understood thimble types, materials, and durability, it’s equally important to know how to maintain them for maximum lifespan.

Ensure correct installation techniques, conduct regular inspections to prevent corrosion, and provide proper storage according to each thimble material’s characteristics.

Optimal thimble performance also depends on selecting high-quality, reliable products—such as those from SpanSet Indonesia. If you need help choosing the right thimble for your wire rope, consult us for further guidance.