A wire rope clip is a simple yet crucial tool for ensuring the safety of a wire rope system.

Understanding the Wire Rope Clip: An Essential Rigging Instrument

The wire rope clip is a key component in rigging and load‑lifting systems. In Indonesia, it’s often called by various names such as “kuku macan,” wire clamp, or sling clamp.

The term “kuku macan” (tiger’s claw) refers to its shape and function, which grip the wire rope firmly like a tiger’s claw. This tool secures and holds the wire rope end so it won’t slip or come loose during use.

What Is a Wire Rope Clip?

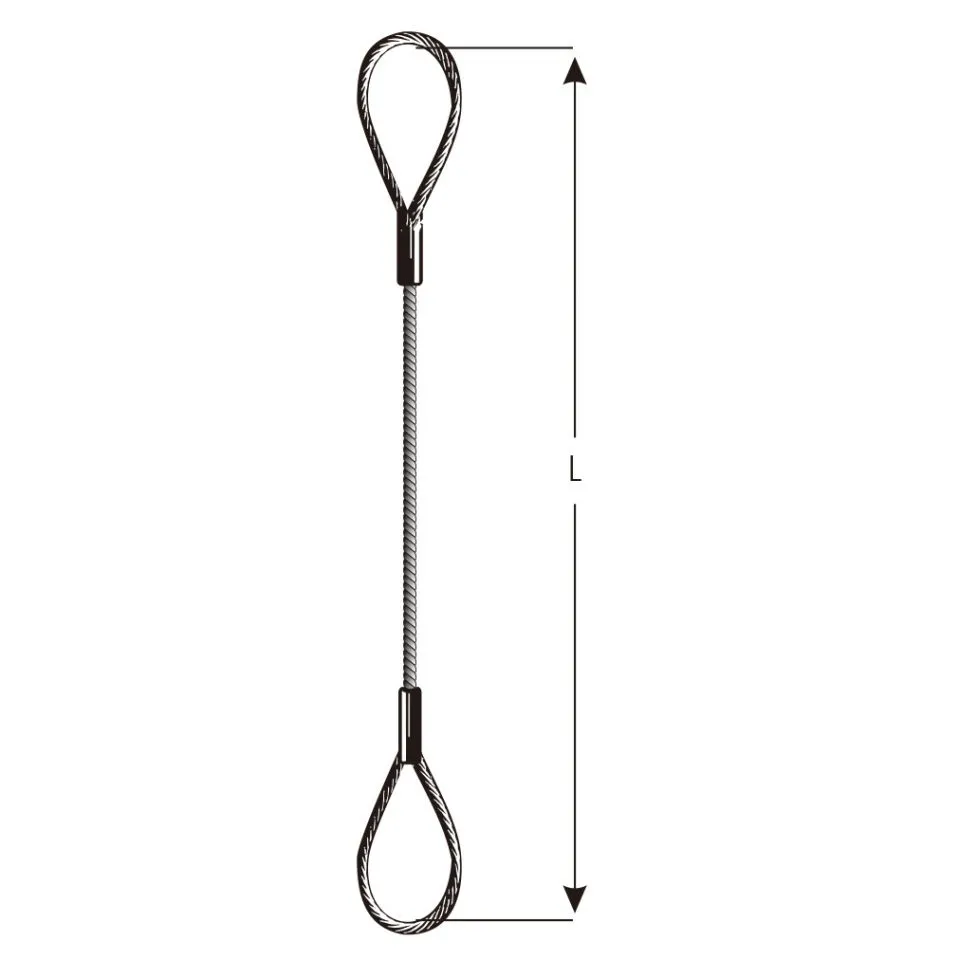

A wire rope clip is specifically designed to secure the end of a wire rope by forming a strong loop or eye without permanent methods like welding. This provides flexibility for installation and removal as needed.

A wire rope clip consists of three main parts:

- Nuts: Tighten the U-bolt to keep the connection strong and secure.

- Saddle: The base piece that supports the wire rope.

- U-bolt: A U-shaped clamp that locks the wire rope onto the saddle.

Functions and Advantages of a Wire Rope Clip

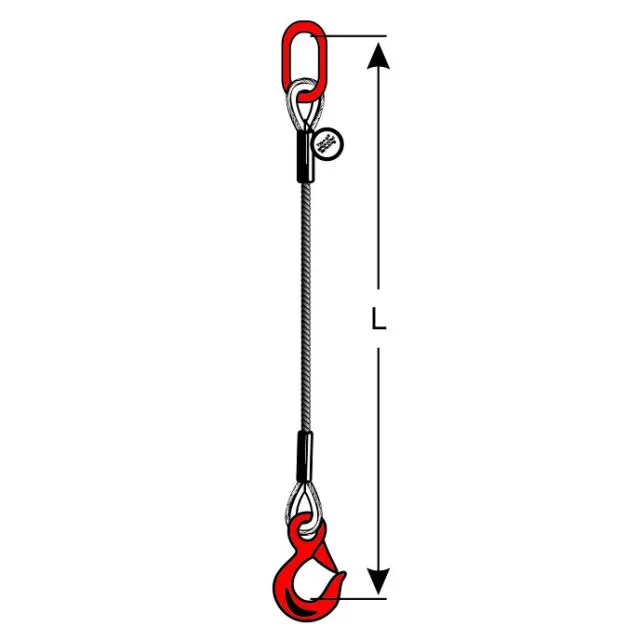

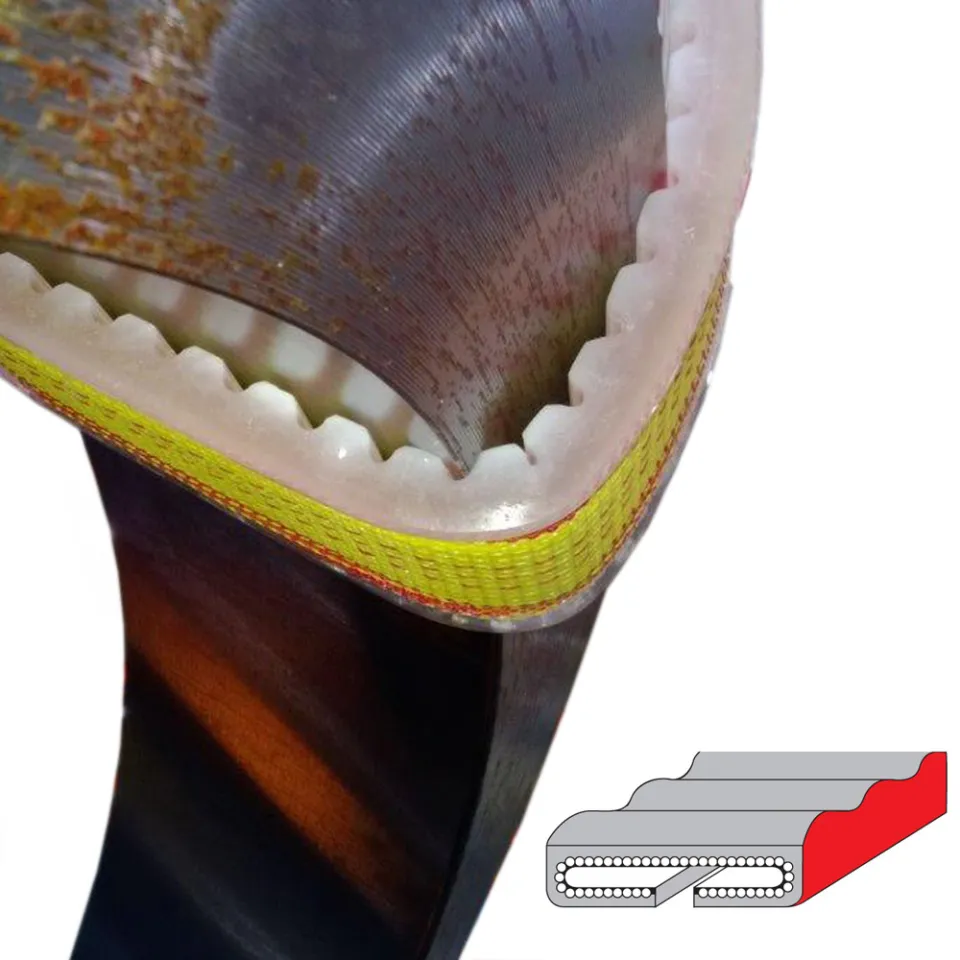

The primary role of a wire rope clip is to create a termination or splice on a wire rope without permanent techniques. With this tool, wire rope can be used for lifting, pulling, and securing applications, depending on its type and specification.

Wire rope clips come in various sizes and shapes to suit user needs. Some designs include additional features to enhance safety and installation efficiency.

How a Wire Rope Clip Works

A wire rope clip works by clamping two parts of the wire rope between the U-bolt and saddle. As the nuts are tightened, the rope is gripped firmly, forming a strong, secure loop without welding or other permanent methods.

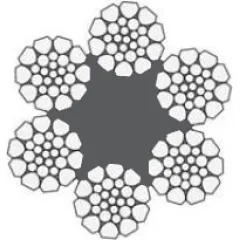

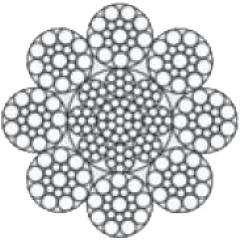

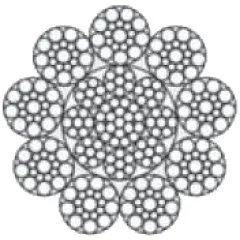

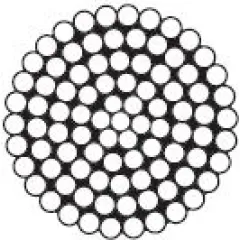

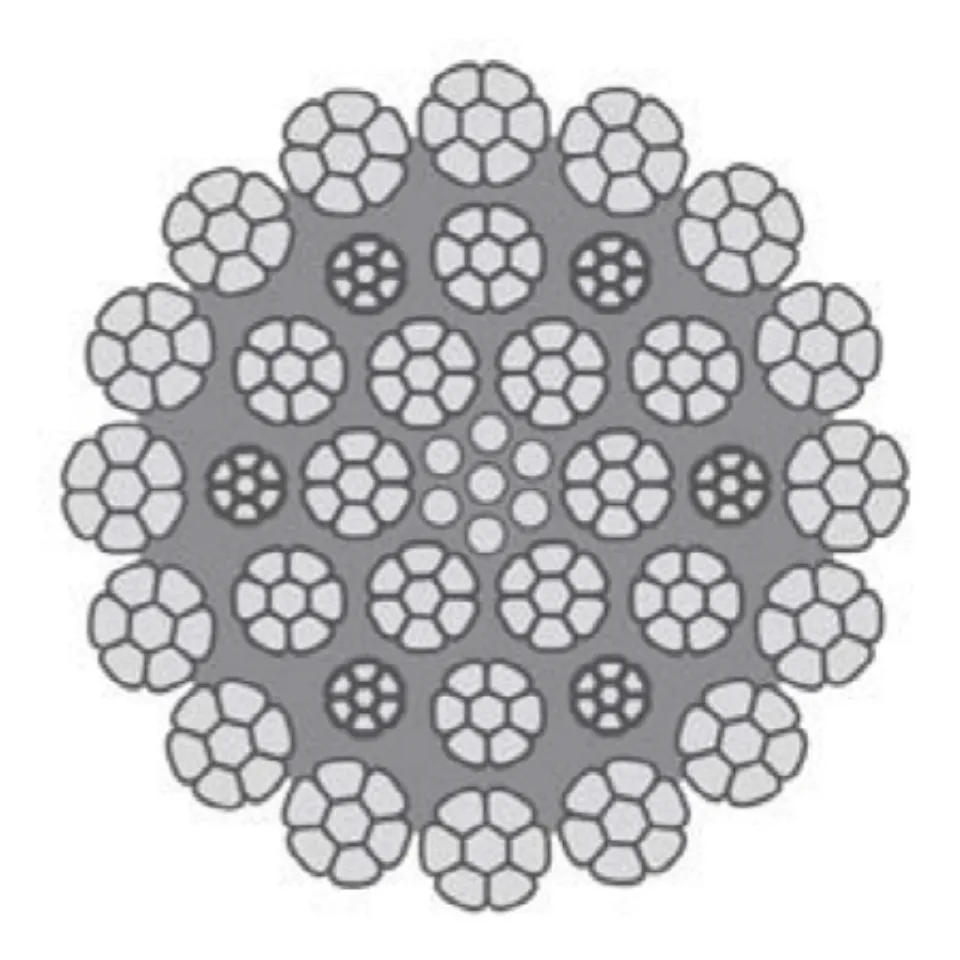

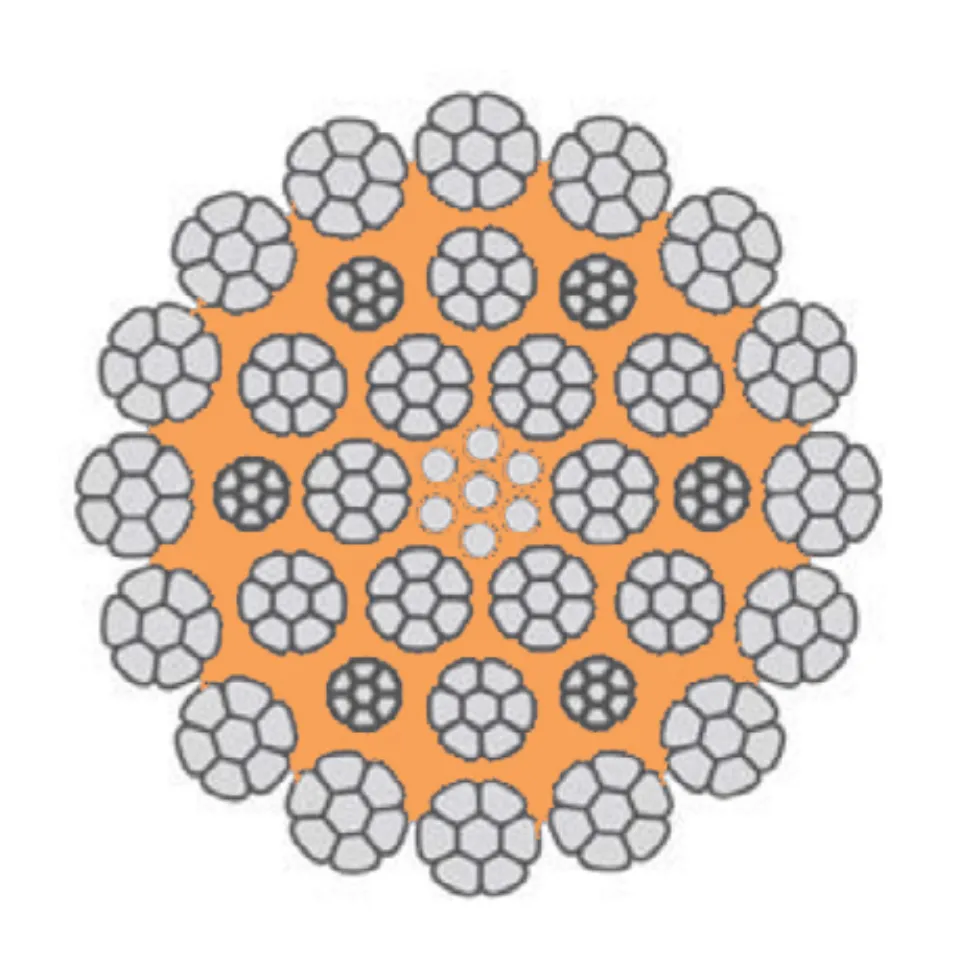

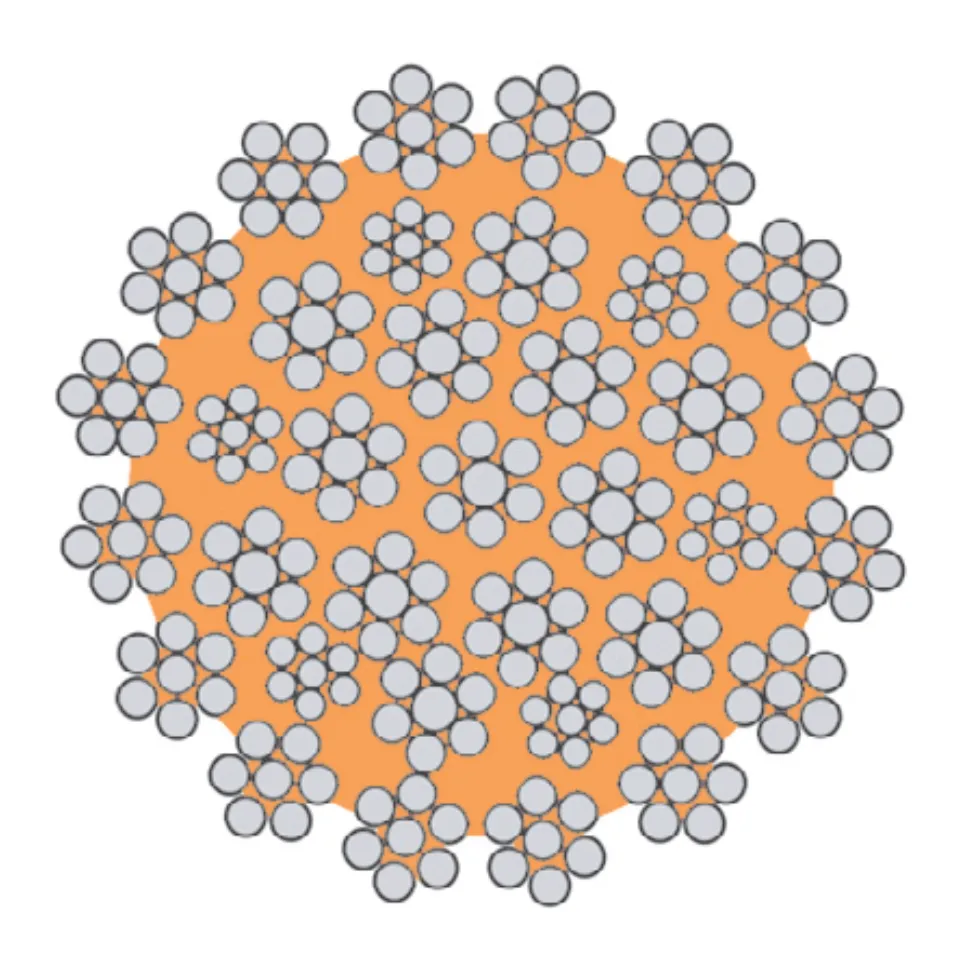

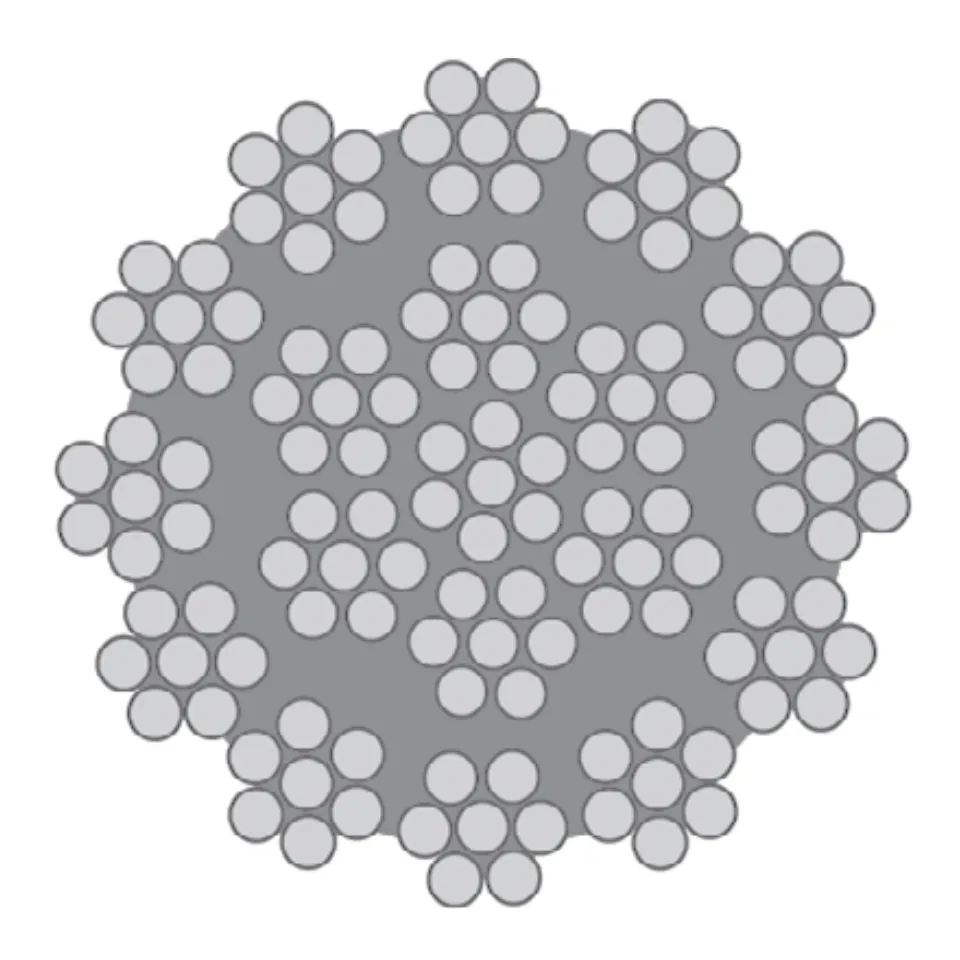

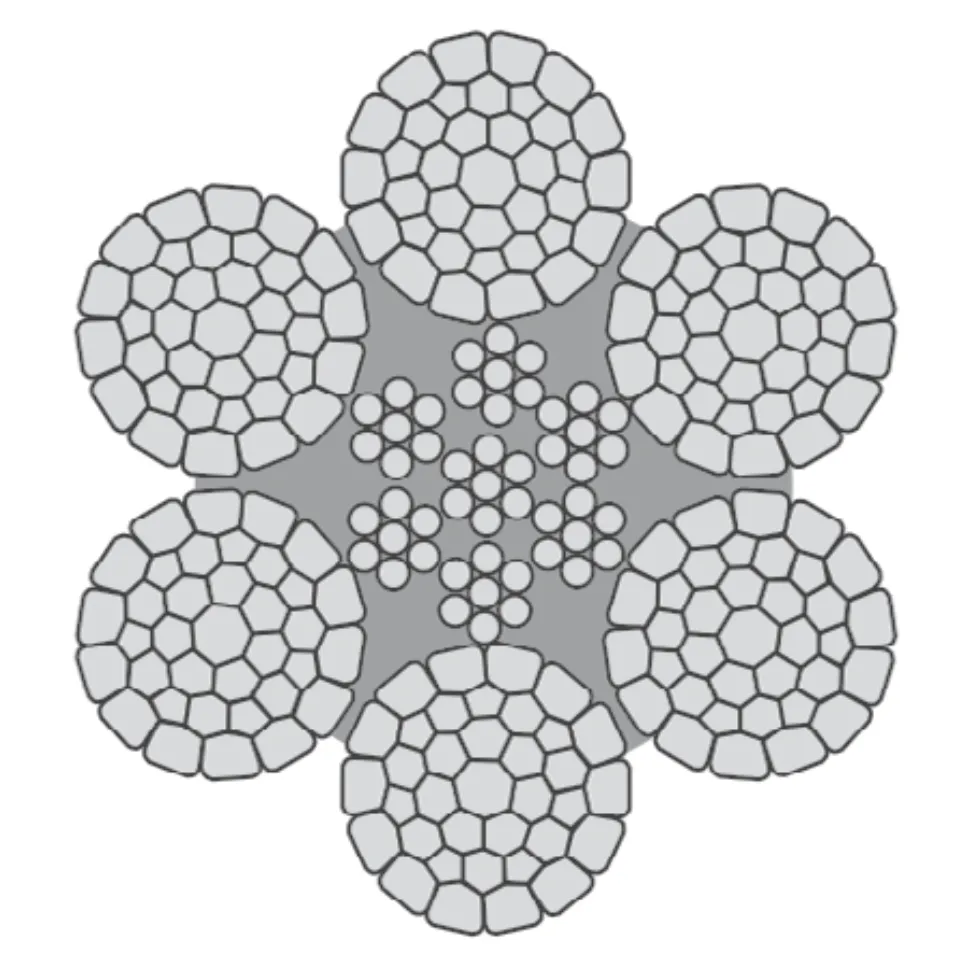

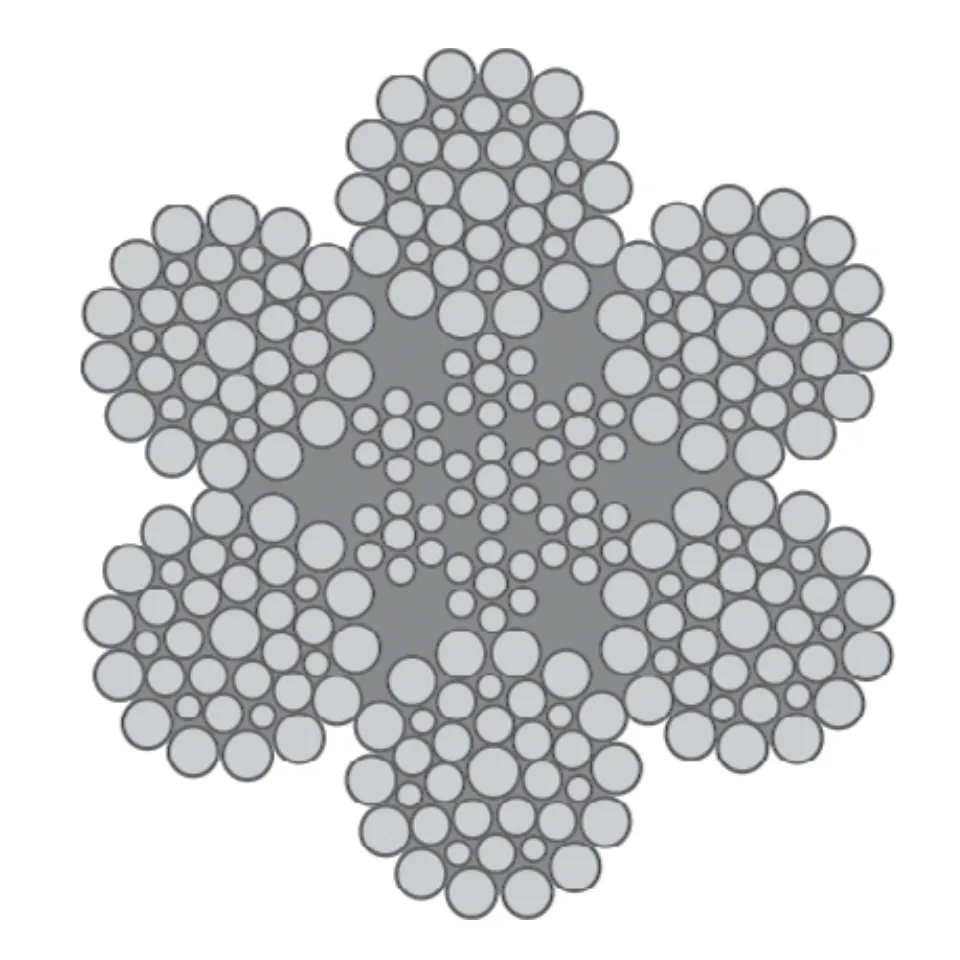

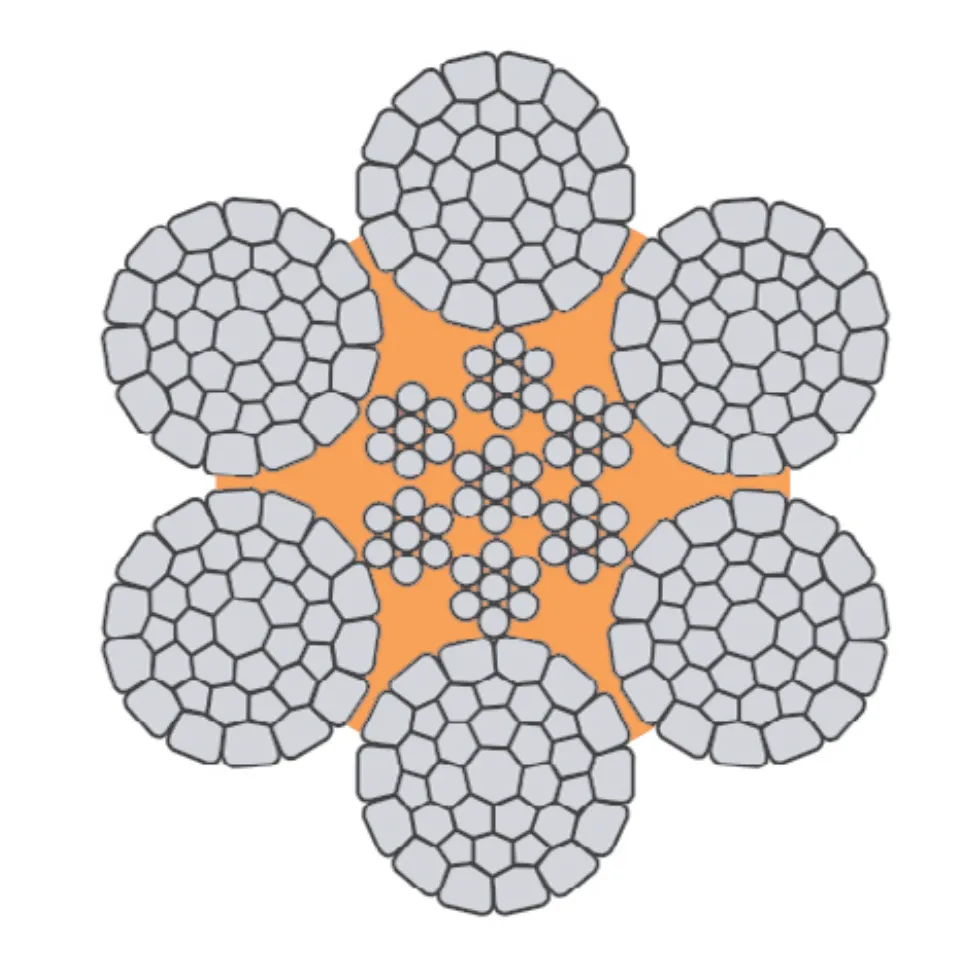

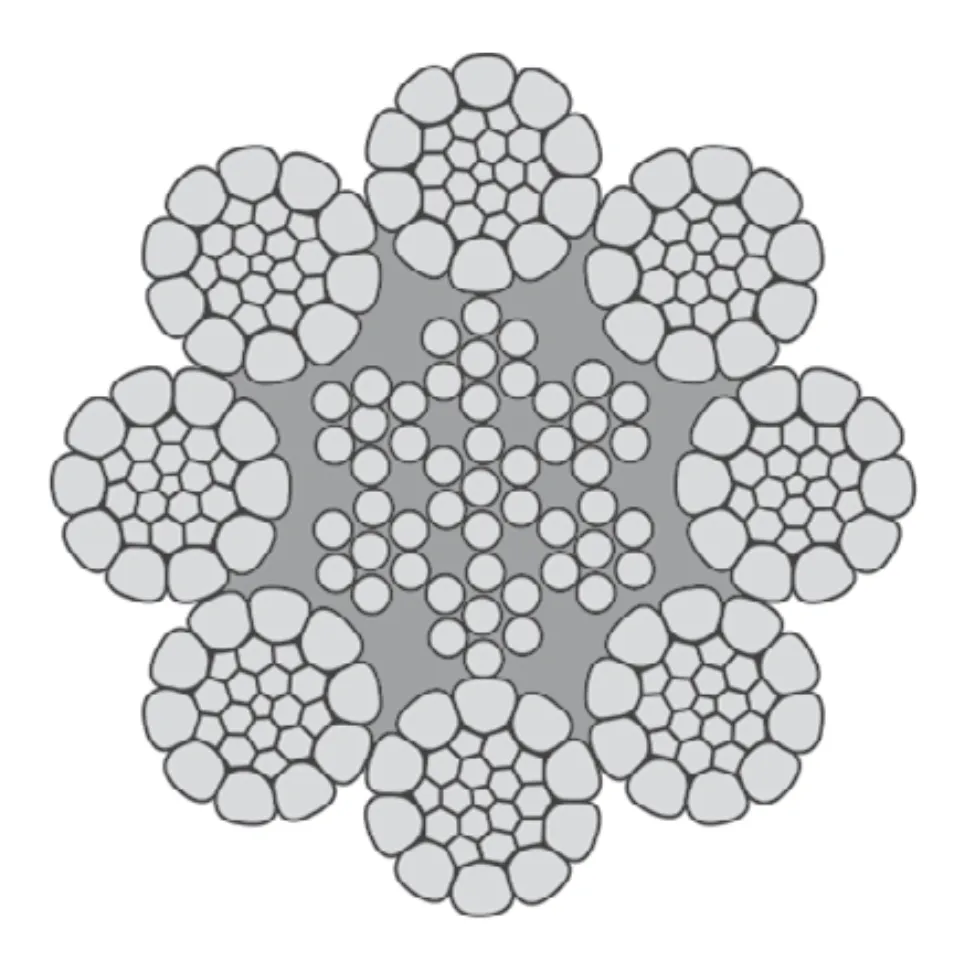

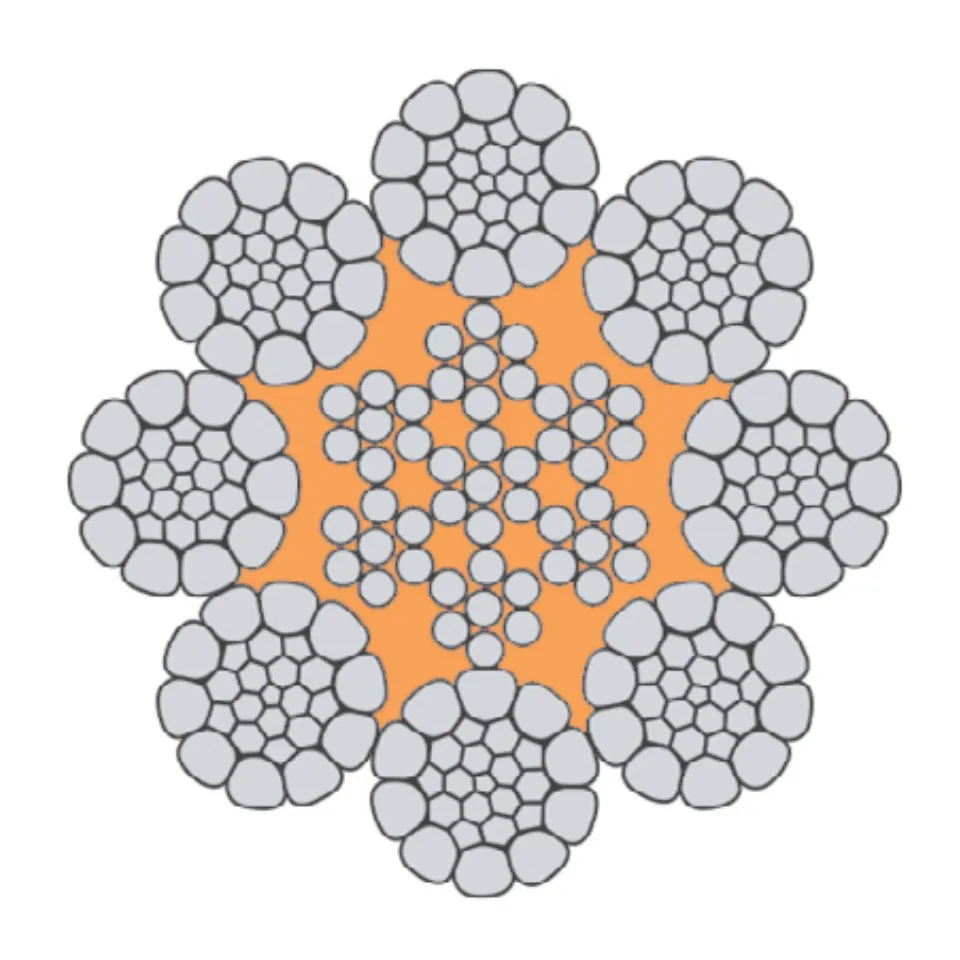

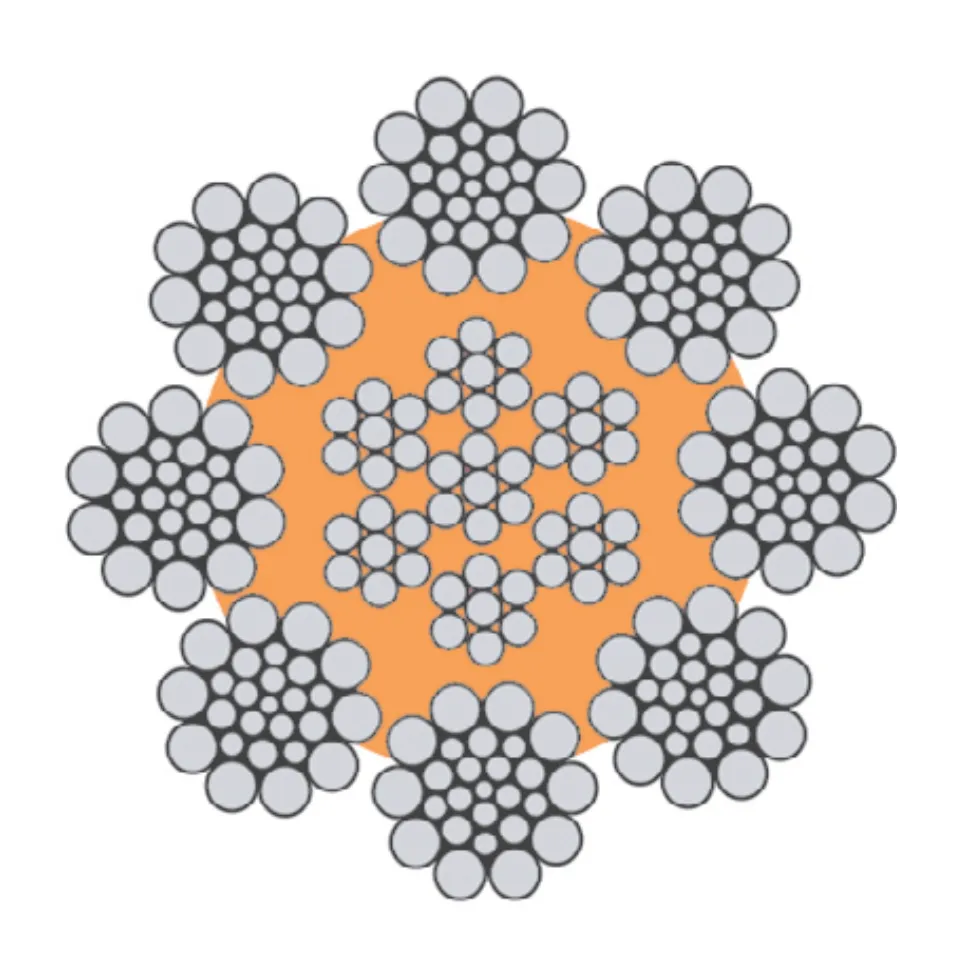

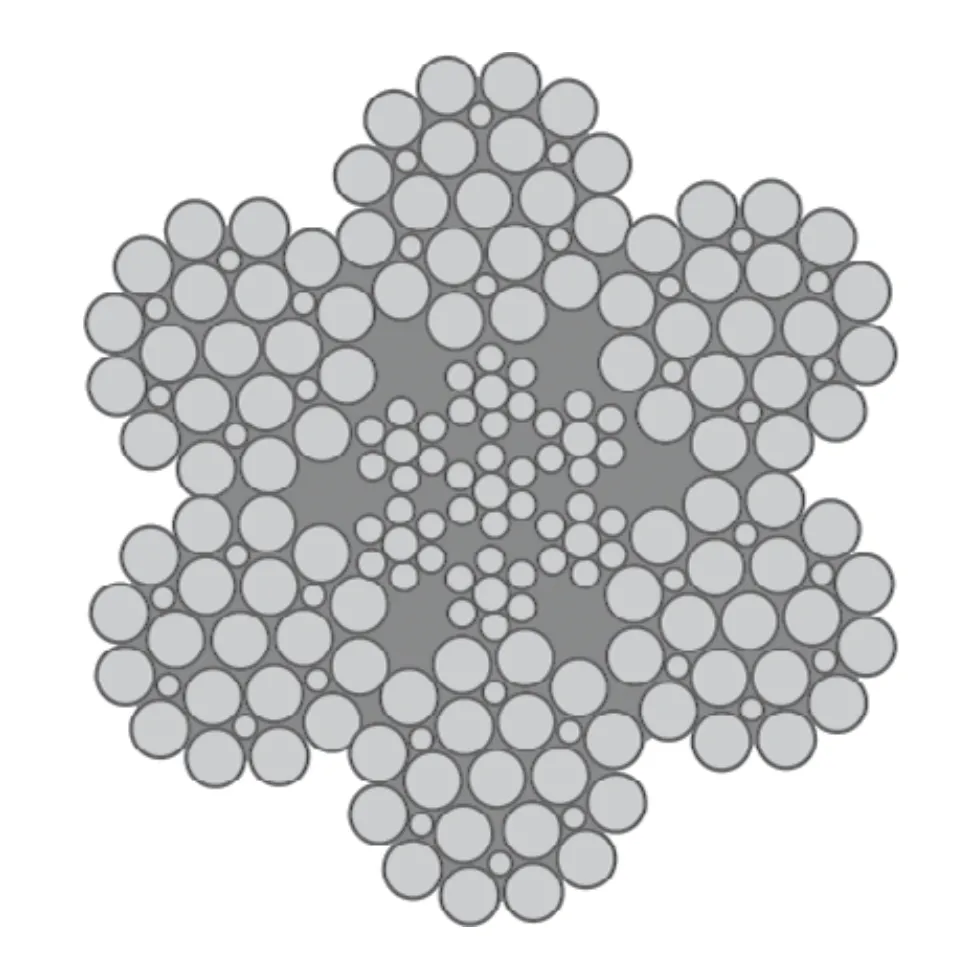

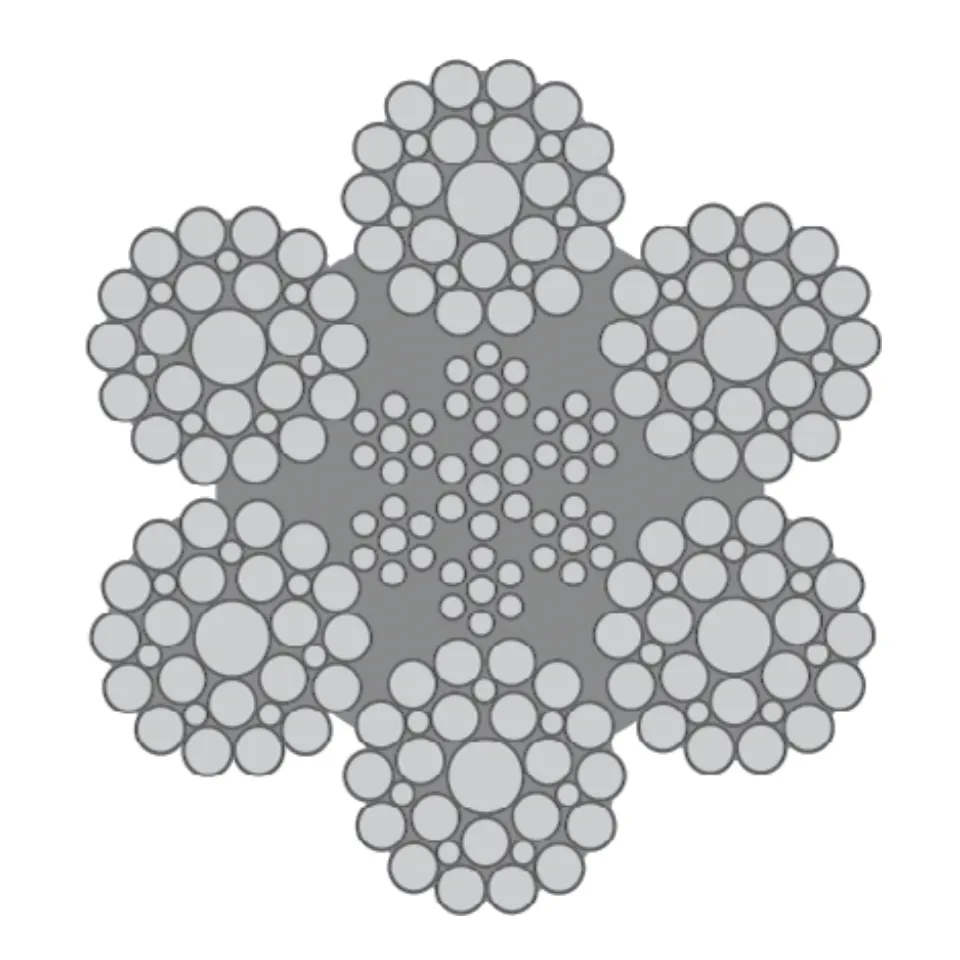

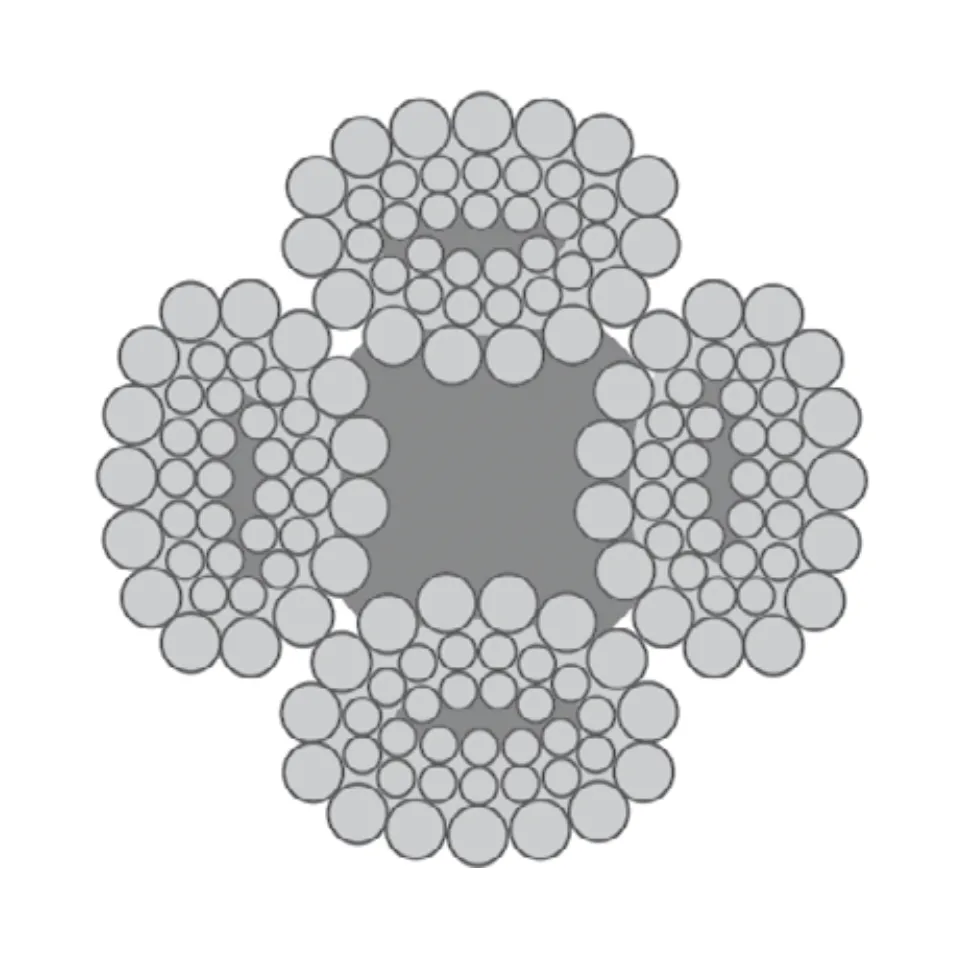

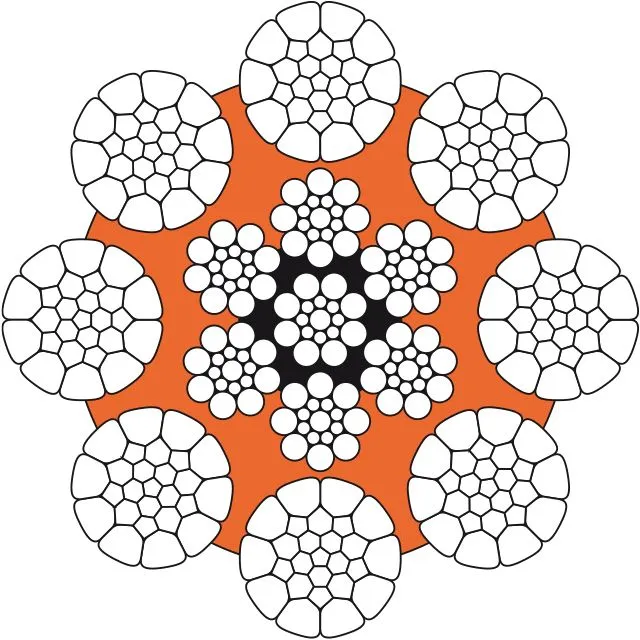

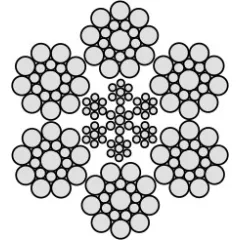

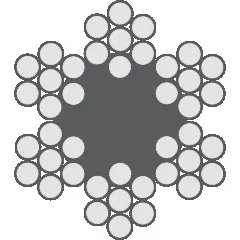

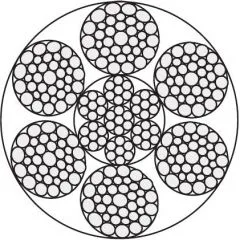

Jenis Wire Rope Clip Berdasarkan Konstruksi

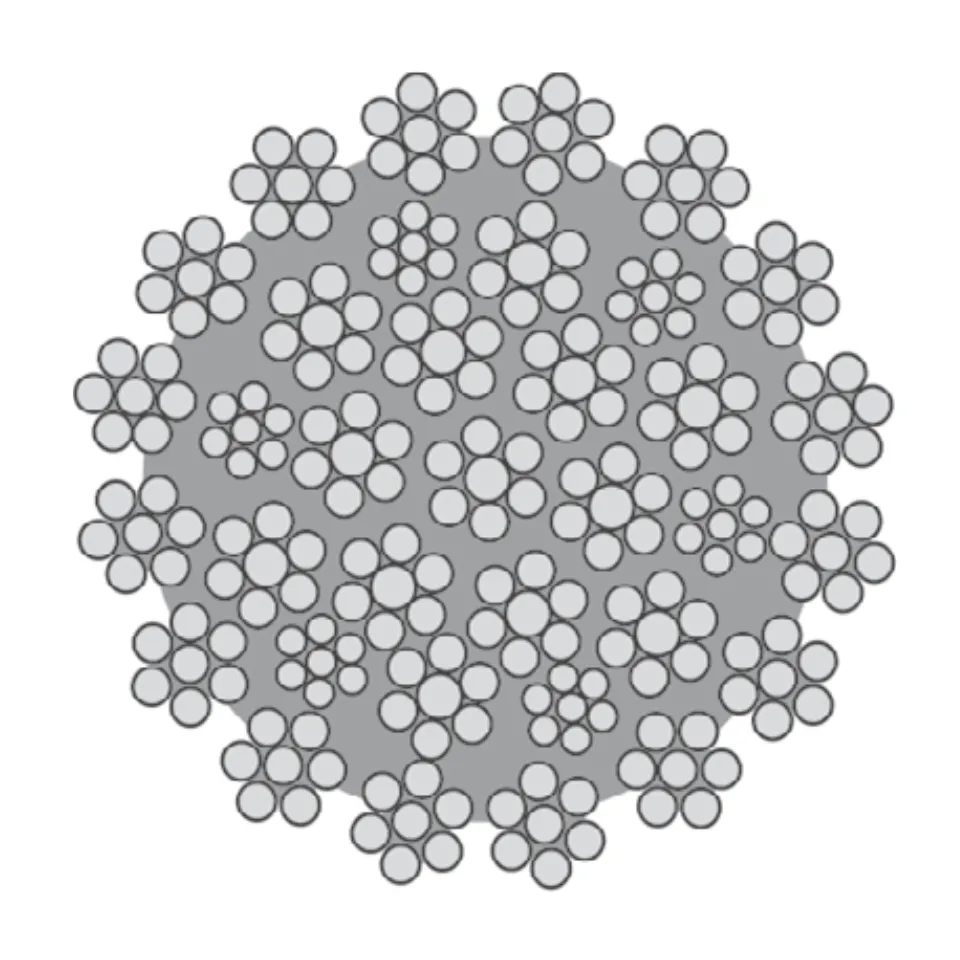

Penggunaannya sudah meluas di berbagai industri yang memerlukan solusi sambungan wire rope yang fleksibel. Wire rope clip tersedia dalam berbagai jenis, dapat dipilih berdasarkan bentuk dan ukuran wire rope yang digunakan.

U-Bolt Clip for Light-Duty Projects

This type is the most commonly used for light to medium applications. It’s suitable for temporary needs or lighter loads.

Drop-Forged Clip for Heavy-Duty Loads

Manufactured through a forging process, the drop-forged clip offers high strength and is ideal for heavy-duty applications such as lifting and rigging.

Malleable Iron Clip for Temporary Applications

Made from malleable iron, this type is more economical and often used for temporary applications. However, it is not recommended for heavy loads.

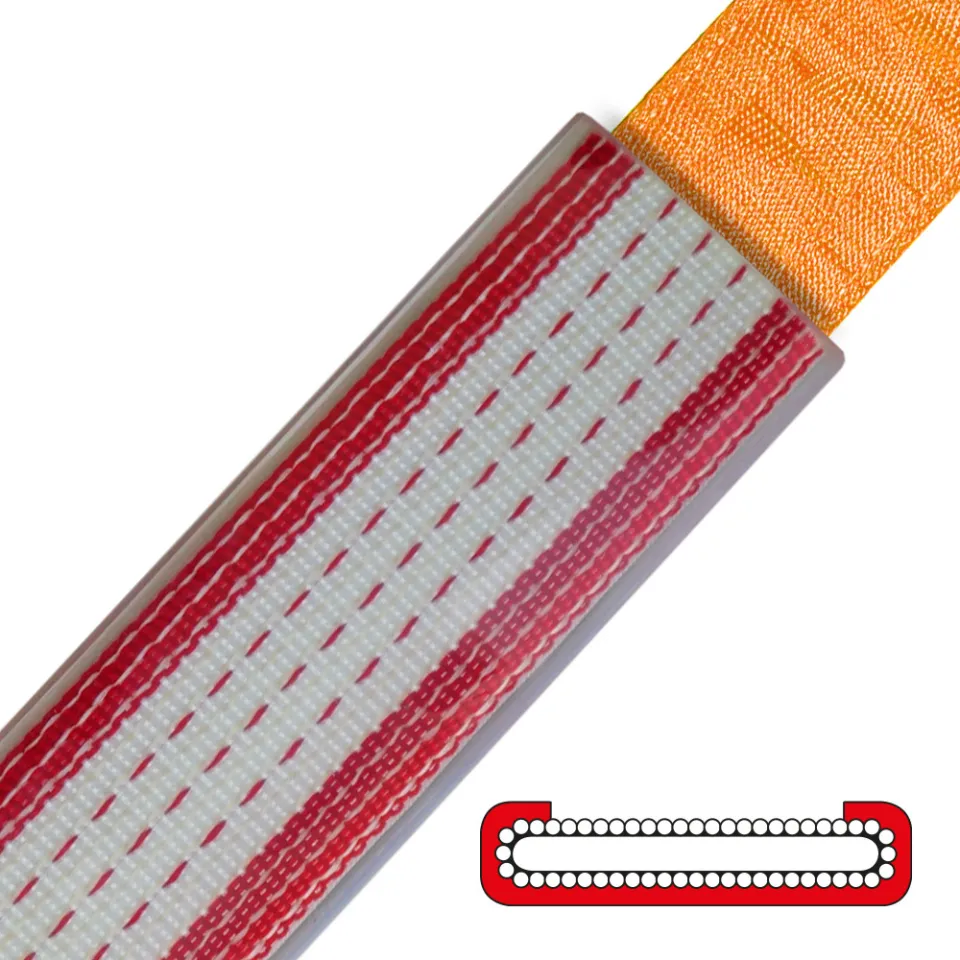

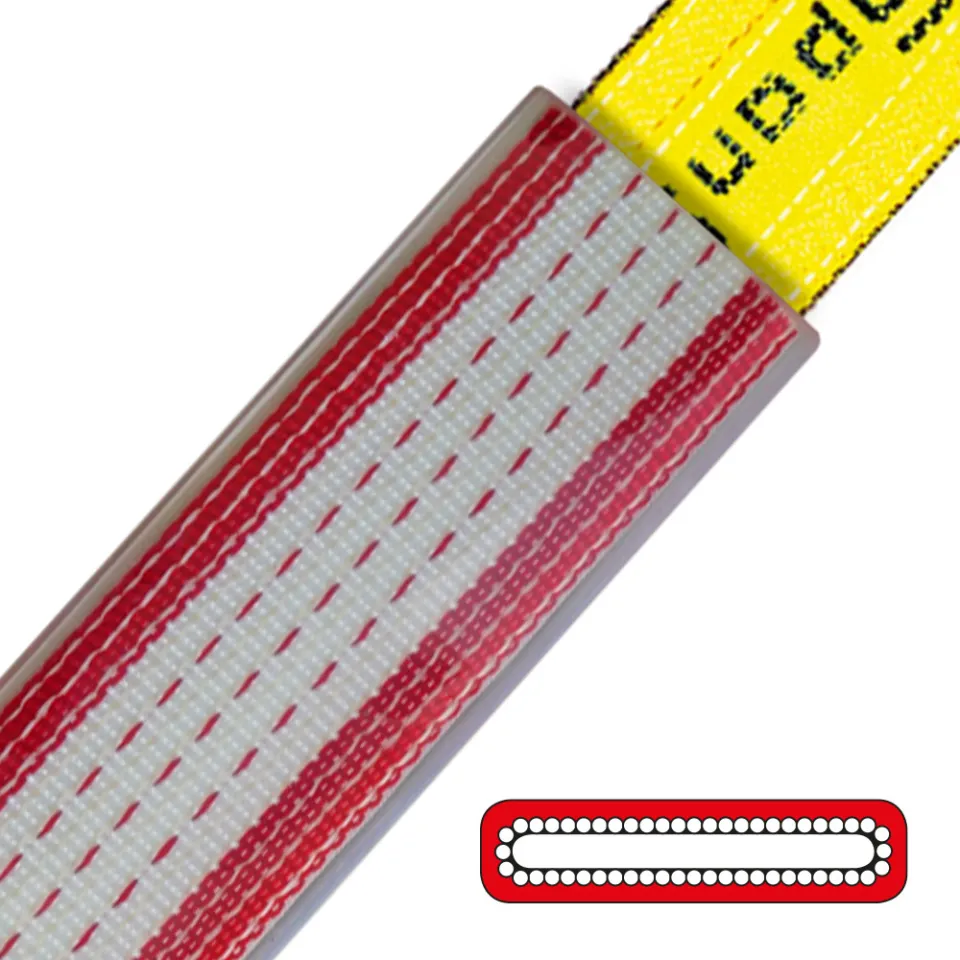

Double Saddle Clip

Equipped with two saddles to provide more even pressure distribution on the wire rope, thereby reducing the risk of deformation or damage.

How to Choose the Right Wire Rope Clip?

Selecting the correct wire rope clip is essential to ensure safety and optimal performance in rigging and load‑lifting applications.

A wire rope clip secures the end of a wire rope, so selection must consider factors such as size, manufacturing standards, and resistance to the working environment.

Here is a guide to help you choose the appropriate wire rope clip for your needs.

1. Clip Size Matching Wire Rope Diameter

Choose a wire rope clip sized to your rope’s diameter so that its grip is optimal without damaging the steel strands.

Before purchasing, check your rope’s diameter specifications and ensure the clip you select is compatible.

2. Manufacturing Standards (ASME or DIN)

To guarantee quality and safety, ensure the wire rope clip meets international standards such as ASME B30.26 or DIN 1142 (or other relevant standards).

These standards certify that the product has undergone rigorous testing and is designed for heavy‑duty use. Using non‑compliant products increases the risk of failure during operation.

3. Resistance to Working Environment

For applications in extreme environments such as marine or heavy industry, choose wire rope clips with corrosion protection, such as galvanized or stainless steel versions.

These materials are designed to withstand wet, humid, or chemically aggressive conditions for extended service life.

How to Use a Wire Rope Clip Safely

Selecting the right wire rope clip isn’t enough without understanding proper usage.

Incorrect installation can reduce grip strength and increase accident risk. Here are key steps to ensure safe use of wire rope clips:

Number of Clips Required

The number of wire rope clips used should correspond to the length and diameter of the wire rope.

Typically, a minimum of three clips is required for standard applications to ensure optimal gripping strength.

However, for heavy‑load or extreme‑condition applications, the number of clips may need to be increased per the manufacturer’s recommendations.

How to Tighten in Saddle-and-U-Bolt Mode

When installing a wire rope clip, place the saddle on the live end of the wire rope and the U‑bolt on the dead end. This configuration prevents slippage and maintains optimal grip on the steel strands.

Tighten the nuts gradually using the torque values recommended by the manufacturer to achieve the best result.

Periodic Inspection and Maintenance

Always check the tightness of the nuts, the condition of the wire rope clip, and look for signs of wear or deformation. Routine inspections are crucial to ensure safety and reliability in use.

By understanding the functions and types of wire rope clips, you can choose the right tool for your needs, ensuring safety and optimal performance in every rigging and lifting application.

Not only wire rope clips, but it’s also important to select the correct, safe, and high-quality wire rope for your needs. For more in-depth information on wire ropes and their types, you can read the following article: